Selector...

The first selector exist in a system for wastewater treatment by means of activated sludge process patented in 1972 by

Chudoba, Grau, and Dohanyos from the Prague Institude of Chemical Technology in Czechoslovakia.Their arrangement had the

inlet part of an aeration basin divided into several compartments, with the return sludge introduced in the first

compartment together with the treated wastewater. The compartmentalized inlet part of the aeration basin is called a

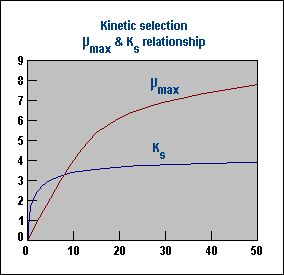

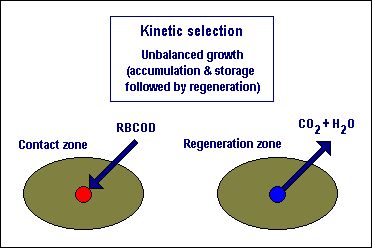

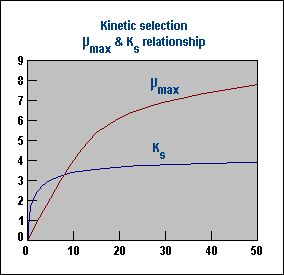

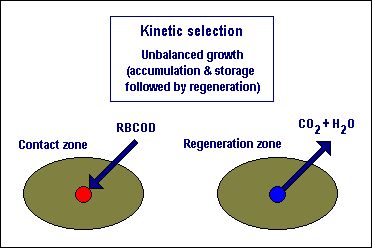

selector but terms like premixing zone or initial contact zone are also used in the literature. This layout exploits the

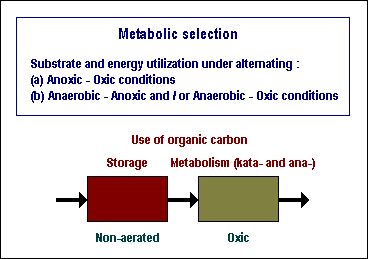

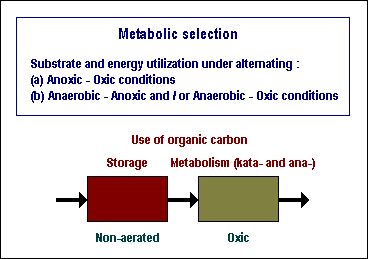

so-called kinetic selection.With the development and introduction of activated sludge modifications for biological nutrient

removal, the effect of anoxic and anaerobic conditions on the growth of filamentous microorganisms was also studied. The

selection mechanism is based on the ability of microorganisms to utilize carbon and energy sources under different

cultivation conditions and the phenomenon was called metabolic selection. In modern activated sludge systems both selection

mechanisms, i.e., kinetic and metabolic selection, are combined to achieve good settling properties.

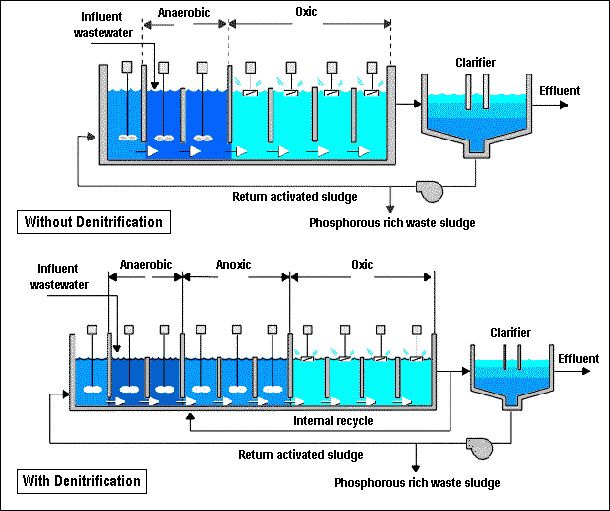

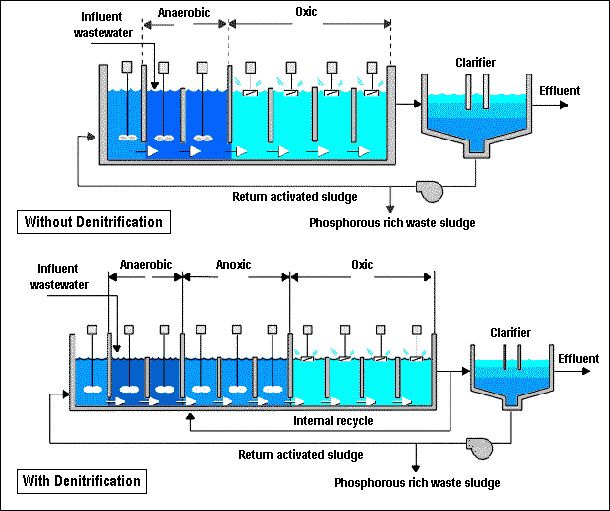

A / O Process...

A basic A/0 system will yield simultaneous biological removal of both BOD and phosphorus. Where only BOD removal is

required, the basic process is optimized to provide significant performance benefits relative to conventional

activated-sludge processes. In either case, the same basic configuration and biological processes, shown above, are

utilized. The A/0 process, which uses an anaerobic selector to achieve enhanced performance, is a high-rate variation

of the conventional activated-sludge process. The anaerobic selector is established by mixing and contacting influent

BOD-containing wastewater with recycled activated sludge in the absence of supplied oxygen or oxygen-containing gas.

In a subsequent step, the anaerobically formed mixed liquor is aerated in an oxic zone and finally separated in a

secondary clarifier, which functions in the same manner as in conventional activated-sludge processes.

Anaerobic Zone : Anaerobic zone detention time is set at the minimum necessary to ensure the development and

maintenance of the A/0 system biomass, without concern for maximizing phosphorus release. For municipal waste, this is

typically between 30 and 60 minutes based on the design-average flow of influent. As the wastewater passes through the

anaerobic zone, most of the influent BOD is absorbed into the biomass. BOD, both sorbed and unsorbed, is then oxidized

in the oxic zone.

Oxic Zone : Various laboratory, pilot-plant, and full-scale studies have shown that an A/0 system will remove BOD

when oxic detention time is less than the minimum time needed to fully oxidize the BOD stored within the A/0 biomass. This

biomass will function acceptably for BOD removal while maintaining a reservoir of stored, unoxidized BOD within the sludge.

This unoxidized BOD is removed from the system through the normal wasting of sludge from the system. Since oxygen

requirements are directly related to the amount of BOD oxidized, operating the A/0 system with- out fully oxidizing the

BOD in the oxic section allows for a net reduction in the amount of oxygen that must be transferred into the mixed liquor.

The net result is a reduction in oxygen or horse- power used for the same amount of BOD removal compared to a conventional

activated-sludge system. Oxygen savings of 15 percent or more can be achieved for A/0 systems compared to conventional

activated-sludge systems. The detention time of the oxic zone is determined by the rate of biological oxidation of stored

BOD, the rate of sorption and oxidation of unstored BOD, the degree of oxidation desired, and mass transfer characteristics

of the aeration equipment.

The A/0 Ditch Process is the application of the A/0 Process in an oxidation ditch layout. The A/0 Process has been employed

in full-scale operation since 1979, and consists of a staged anaerobic selector followed by multiple oxic reactors operating

in series. The anaerobic selector was initially developed to improve the settling characteristics of activated sludge by

inhibiting the growth of filamentous bacteria, which cause bulking sludge. Filamentous bacteria are obligated aerobes

passing the RAS through the anaerobic selector, which is devoid of free and/or combined forms of oxygen compounds; the

filamentous bacteria are not able to proliferate. The anaerobic selector also promotes biological phosphorus removal from

wastewater, which is described in detail in the description of the BioDenipho Process. The combination of minimal

filamentous populations and an increased phosphorus concentration in the biosolids, produces a dense rapidly settling

floc. As a result, effluent solids concentrations are reduced while the RAS concentration is increased. The increased RAS

concentration enables the associated pumping rate to be reduced. In the A/0 Ditch Process, the staged anaerobic selector

is followed by an oxidation ditch. Figure given above illustrates the layout applied for the 1.6 MGD Hollister, MO A/0

Ditch. Krüger incorporates automatic DO control into the operating strategy of the A/0 Ditch Process, which maximizes

simultaneous denitrification and minimizes energy consumption. Biological phosphorus removal eliminates the expense and

excess sludge generated by chemical precipitation processes. In addition, the inhibited filamentous growth ensures

consistent process performance during difficult treatment conditions, including low F:M ratios and low DO concentrations.

Another attractive feature of the A/0 Ditch Process is that upon expansion, nitrogen removal can be incorporated into the

treatment scheme by adding anoxic tanks and operating in the A2/0 Ditch Process, or by adding a second ditch and controls

to operate in the BioDenipho Process. Regardless of whether your plant's effluent limitations include phosphorus removal,

or simply require 30/30 treatment, the advantages offered by the A/0 Ditch Process warrant your consideration.

The BioDenipho Process...

The BioDenipho process incorporates anaerobic selector technology to promote biological phosphorous removal from the

wastewater. It combines the flexibility and energy efficiency of the BioDenitro Process with the advantages offered by

an anaerobic selector. This results in a highly-efficient Biological Nutrient Removal (BNR) system. A three-stage

anaerobic selector is incorporated prior to the distribution chamber. The anaerobic residence time is approximately 3

hours based on a flow of 3.0 MGD for U.F. Water Reclamation Facility. This is not long enough to promote the buildup of

sulfides or other noxious products associated with anaerobic treatment processes. Each stage of the anaerobic selector

contains a submerged mixer designed to provide gentle agitation of the mixed liquor while minimizing turbulence at the

liquid surface. The mixer is driven by a gear-reduced, waterproof submerged motor. The anaerobic selector separates

activated sludge metabolism into two steps: BOD uptake and BOD oxidation. The return activated sludge (RAS) enters the

anaerobic selector, where it is mixed with influent wastewater. By passing the RAS and influent through the anaerobic

selector, microorganisms capable of using stored polyphosphate as an energy source are proliferated. This energy is used

to transport BOD into their cellular structure when free or combined forms of oxygen are not available for respiration.

In the anaerobic zone, where substrate (BOD) concentration is high, the absence of oxygen causes the microorganisms to

release the stored intracellular polyphosphates by decomposition to simple orthophosphates. The decomposition of

polyphosphate to orthophosphate results in an increase of soluble phosphorus in the mixed liquor and also releases

energy. The energy is used by the microorganisms to transport soluble BOD through the cell wall and store the soluble

BOD inside the cell. Thus, the BOD concentration in the mixed liquor is reduced without the use of oxygen. Typically,

the anaerobic selector is a three-or-four stage reactor equipped with submersible mixers to maintain biosolids in

suspension. Return activated sludge (RAS) is discharged to the first stage selector, while raw influent is directed

to the second stage. By staggering the RAS and raw wastewater influent location, the volatile fatty acids and soluble

BOD, which promote phosphorous release, are not consumed during RAS denitrification. As an added benefit, the anaerobic

selector inhibits the growth of filamentous bacteria that cause bulking sludge.

In the subsequent anoxic phases, nitrates are present from prior oxic phases. Microorganisms capable of biological

denitrification are favored in this phase. The carbon source required for biological denitrification is provided by the

BOD in the influent wastewater; no additional carbon source is required. In the oxic phase, the organisms in the presence

of dissolved oxygen convert the stored and extracellular BOD to CO2, water, and increased cell mass. A portion of the

energy from this reaction then goes to recreating the intracellular polyphosphate using the orthophosphate released in

the anaerobic zone. Since new cells are grown, the amount of phosphate removed from solution is greater than the amount

previously dissolved in the anaerobic zone, thus affecting net phosphate removal. In the second stage, denitrified RAS

is contacted with the influent wastewater in the absence of free or combined forms of oxygen. The anaerobic environment

stresses the microorganisms, which begin to break down stored polyphosphate into orthophosphate. Throughout the remainder

of the anaerobic selector, orthophosphate is expelled from the microorganisms releasing energy that is used to absorb BOD

into their cells. In subsequent anoxic and oxic phases, the BOD is oxidized and the cells reproduce. In the oxic phases,

these new cells, along with old cells, replenish the phosphorous reserved within their cells. This results in a net

phosphorous uptake. Phosphorus removal from the wastewater is ultimately achieved by wasting phosphorous-rich sludge from

the system. Phosphorous is removed from the system as a fixed biological material in the waste sludge. The amount of

phosphorous in the sludge will be dependent upon the amount of BOD and phosphate in the influent and the volume of sludge

produced.

Other applications...

Two researchers described a successful case in Fayetteville, Arkansas where the compartmentalized anaerobic zone introduced

for achieving the EBPR mechanism also solved the bulking problems. The tested system consisted of a six - compartment

anaerobic zone followed by a four - compartment oxic zone. The mixed liquor hydraulic retention times in individual zones

averaged 1.2 h and 8.3 h, respectively. The system was operated at a biomass retention time of about 10 days (winter) and

5 days (summer). The conditions in the anaerobic compartmentalized zone were truly anaerobic during the evaluation period,

because there was no internal recycle of nitrified mixed liquor from the oxic to the anaerobic zones. Once the population

of Poly - P bacteria was stabilized in the biocenoses of this activated sludge, the SVI - values stabilized in a range of

60 - 80 mL / g. In his surveys of bulking control technologies, an author gave another example of the positive effect of

an anaerobic zone on activated sludge settling properties. The original wastewater treatment plant in Newark, Ohio suffered

from long - term poor performance due to frequent bulking and foaming problems. In 1988, a new plant was brought on - line

in which a three - compartment anaerobic / anoxic zone was included. The SVI values in the new plant decreased from the

initial 100 - 400 mL / g to 80 - 200 mL / g with an average of 120 mL / g. Metabolic selection in anaerobic / oxic

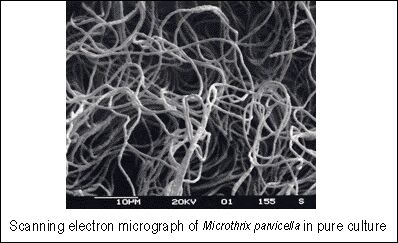

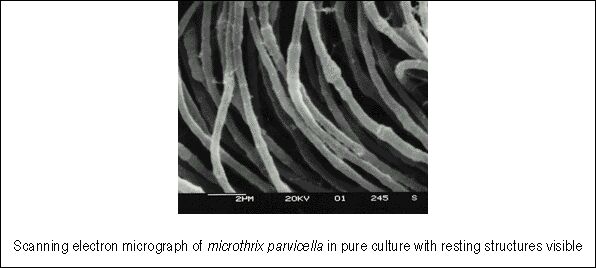

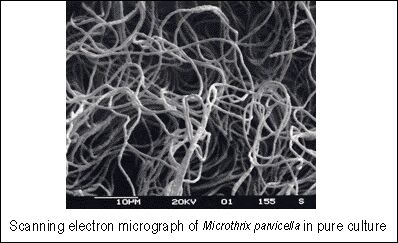

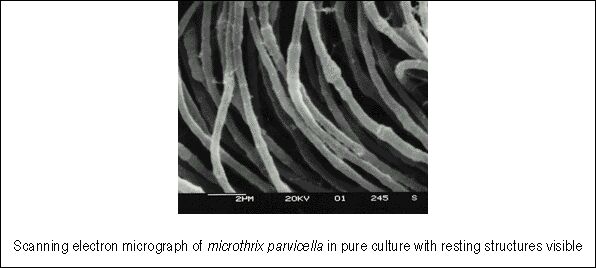

cultivation conditions, however, does not seem to be effective in suppressing, all known filamentous microorganisms in

activated sludges. Examples from the Netherlands and from South Africa (Johannesburg Northern Works), when the anaerobic

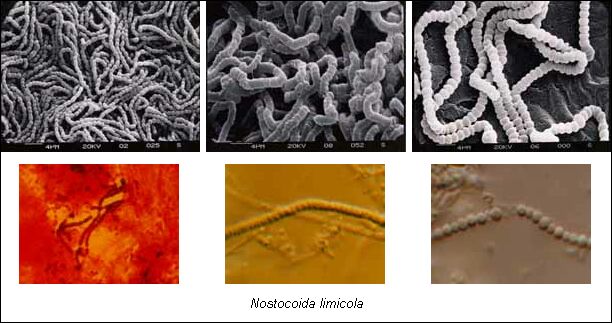

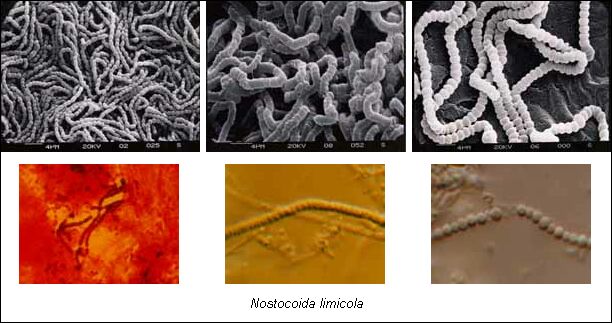

zones failed to control the growth of Microthrix parvicella, were given in the section of morphology of filaments. From

the survey of properties of most common Eikelboom types, at least two other filamentous organisms seem to be capable of

competing with floc - formers under alternating anaerobic / oxic conditions, namely Type 0092 and Nostocoida limicola.