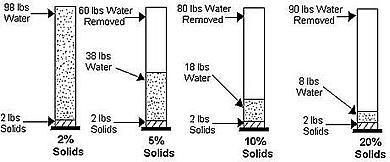

It is generally desirable to handle the most concentrated sludge possible for the following reasons: To save storage space in a digester or to provide a longer digestion period for solids; to save pumping capacity; to reduce heat requirements in heated digesters because there is less water to be heated; and to reduce heat and power requirements for other types of sludge treatment.

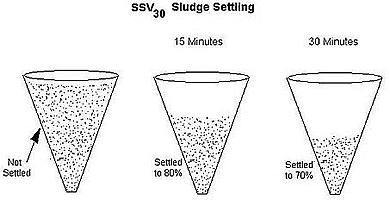

This is for good settling sludge. After 30 minutes if the sludge is sill at 90 %, there will be organics leaving through the clarifier (sludge in clarifiers illustrated above).