Bioreactors degrade contaminants in water with microorganisms through attached or suspended biological systems. In suspended growth systems, such as activated sludge, fluidized beds, or sequencing batch reactors, contaminated ground water is circulated in an aeration basin where a microbial population aerobically degrades organic matter and produces CO2, H2O, and new cells. The cells form a sludge, which is settled out in a clarifier, and is either recycled to the aeration basin or disposed. In attached growth systems, such as upflow fixed film bioreactors, rotating biological contactors (RBCs), and trickling filters, microorganisms are established on an inert support matrix to aerobically degrade water contaminants.

One promising methodology includes the use of active supports (such as activated carbon, which adsorbs the contaminant and slowly releases it to the microorganisms for degradation). The microbial population may be derived either from the contaminant source or from an inoculum of organisms specific to a contaminant. Other applications include wetland ecosystems and column reactors.

Nutrients are often added to the bioreactors to support the growth of microorganisms. Bioreactors are a long-term technology. The process may take up to several years.

Bioreactors are used primarily to treat SVOCs, fuel hydrocarbons, and any biodegradable organic material. The process may be less effective for some pesticides. Successful pilot-scale field studies have been conducted on some halogenated compounds, such as PCP and chlorobenzene and dichloro-benzene isomers. Bioreactors with cometabolites are used to treat PCBs, halogenated VOCs, and SVOCs in extracted ground water.

The following factors may limit the applicability and effectiveness of the process : (a) The dilute nature of contaminated ground water often will not support an adequate microbial population density, and this is especial true for suspended growth reactors. Nutrient addition may be necessary. (b) Very high contaminant concentrations may be toxic to microorganisms and require special design approaches. (c) Air pollution controls may need to be applied if there is volatilization from activated sludge processes. (d) Low ambient temperatures significantly decrease biodegradation rates, resulting in longer cleanup times or increased costs for heating. (e) Nuisance microorganisms may preferentially colonize bioreactors, leading to reduced effectiveness. (f) Residuals from sludge processes require treatment or disposal. (g) Discharge of treated effluents may still be regulated.

"Flow - Chart of the RBC Process - 1"...

"Flow - Chart of the RBC Process - 1"...

"Flow - Chart of the RBC Process - 2"...

"Flow - Chart of the RBC Process - 2"...

Data requirements include contaminants and their concentrations, pH, presence of compounds toxic to microorganisms, contaminant biodegradability, BOD5, COD, suspended solids, flow rate, temperature, and nutrient concentrations.

This is a well developed technology that has been used for many decades in the treatment of municipal and industrial wastewater. However, only in the past decade, studies have been performed to evaluate the effectiveness of bioreactors in treating ground water and leachate from hazardous waste sites. Bioreactor equipment and materials are readily available. As with other pump-and-treat technologies, time needed to clean up is dependent upon subsurface conditions and the rate of desorption of contaminants from subsurface materials.

Startup time can be slow if organisms need to be acclimated to the wastes;

however, the existence of cultures that have been previously adapted to specific hazardous wastes can decrease startup and

detention times.

DOE has demonstrated another biological process, biological destruction of tank waste (BDTW), on the laboratory scale. This

process is a separation and volume-reduction process for supernatant and sluiced salt cake waste from underground storage

tanks. These wastes are usually composed of various radionuclides and toxic metals concentrated in a nitrate salt solution.

The bacteria act as metal and radionuclide adsorbers and also as denitrification catalysts that reproduce themselves at

ambient temperature and pressure. Some degradation of organic contaminants may also occur during the process.

The field demonstration bioreactor tank size is about 100 cubic meters, which corresponds to a waste treatment rate of 2

gpm, sufficient to treat a 1-million gallon tank in 1 year. At the 2-gpm size, the BDTW system is transportable. The

current bioreactor is able to process salt solutions having nitrate concentrations up to 300,000 ppm. The maximum salt

tolerance is being explored. Power usage is estimated at 20 kW for pumping and agitation.

Costs are highly dependent on the contaminants and their concentrations in the influent stream. Biological treatment has

often been found to be more economical than carbon adsorption.

Staging will vary from site to site depending on the

wastestream. The cost to install a single unit with a protective cover and a surface area of 9,300 to 13,900 square meters

(100,000 to 150,000 square feet) ranges from $80,000 to $85,000. Additional cost information can be found in the Hazardous,

Toxic, and Radioactive Wastes (HTRW) Historical Cost Analysis System (HCAS) developed by Environmental Historical Cost

Committee of Interagency Cost Estimation Group.

Only at the interface with air does Acetobacter xylininum grow rapidly. In static culture, this bacterium synthesizes

long strands of cellulose, presumably to float it to the surface. Remarkably, other materials can be converted to these

strands; carboxymethyl cellulose and other compounds support the formation of filaments. While it might be possible to

switch from one medium to another in other types of reactors, our system with a rotating disk reactor is ideal for exposing

the active surface to changing composition of medium.

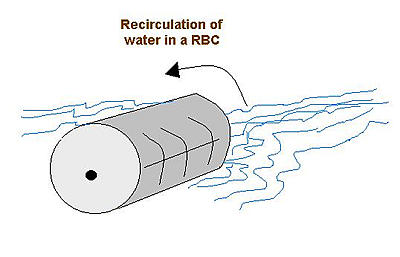

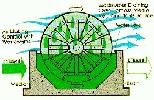

Waste treatment with a rotating biological contactor (RBC) has a 20-year history with some applications with domestic wastes

but more use in industry as a substitute for the old method of trickling filtration (Grady and Lim, 1980). A typical installation

is 5 to 20 meters long with a rotating shaft with many disks of over a meter in diameter on about one centimeter centers.

These dip into a semi-circular trough and carry the film of organisms. As with the trickling filter, the concept is alternate

dousing the culture with nutrient medium and exposing the film to air. The volumetric efficiency of the RBC is high because

much surface is available, and power requirements are low because the disks rotate slowly with only a minor amount of

friction and liquid resistance to overcome.

We are using the concept of the RBC to produce microbial cellulose. When the speed of rotation is too slow, no film forms.

Turning at roughly 12 rpm is highly successful in that a thick film forms in about 24 hours while the control with the

usual surface culture has merely the thin scum that presages a pellicle. By 3 days the disk with film on each side is about

3 cm thick and can be harvested. Stainless steel screens of several different mesh sizes have been tried, but we have not

had plastic disks from commercial RBC's available yet. Stainless steel as fine mesh is not satisfactory because it bends

badly when heavily loaded with cellulose. We have drilled thin Plexiglass to make excellent disks but have found that the

plastic mesh from fabric stores is ideal. No drilling is required, and the coarse mesh allows growth through it to hold the

cellulose tightly. It supports a thick load of gum with little bending.