Lagoon Systems - 3...

Wastewater Lagoon Aeration...

Wastewater lagoon aeration represents one of the most energy intensive operations in the wastewater treatment system, consuming between 50 and 90% of the total energy costs of a typical municipal treatment facility. A general data survey

made available about 20 years ago on municipal and industrial wastewater treatment installations show that there are approximately 1.3 million kw of aeration equipment in place at an installation value of between $0.6 and 0.8 billion

dollars. Operating costs estimated in 1982 were to be about 0.6 billion per year.

The testing of oxygen transfer devices in both clean and process waters is a recent major change that has taken place

in this field. Extensive aeration equipment tests in process waters using new, more accurate techniques have led to a

better understanding of the translation of clean water tests results to process conditions. Diffused aeration is defined

as the injection of gas ( air or oxygen ) under pressure below the liquid surface. The interest in fine bubble aeration

has instigated new equipment development and a multiplicity of new maintenance considerations. Field studies have demonstrated the importance of diffusers placement and tank geometry have produced more efficient system designs.

Experiments on wastewater aeration started in England as early as 1882. They continued on aeration and aerated filter wastewater treatment in England and the U.S. until the activated sludge process was unleashed to the world in April of

1914. In the early experiments, air was introduced through open tubes or perforations. As the activated sludge process investigation progressed, greater economy was sought with smaller bubbles produced by porous media. In 1914, experiments

were made with natural limestone, fire brick, sand and glass mixtures, pumice and other materials. They were all found to

be to dense. In 1915 a porous plate set in a cast iron box was developed. In the following years, experiments with porous media and other media continued.

Diffuser clogging was a problem in numerous cases from the earliest aeration experiments. Around 1915, perforated pipes

were abandoned in favor of diffusers because 90% of the jets had plugged. With the advent of porous diffusers, clogging became an even greater problem. Early work between 1922 to 1924 prompted coarser media use to avoid severe clogging

problems. Mechanical aeration was one answer to the clogging problem. Down draft and up draft type mechanical aerators

were developed to diffuse air efficiently and to solve clogging problems. Another approach to the clogging problem was the development of the large orifice-type diffuser. First developed in the 1950's, these units improved on earlier perforated pipes and were designer for easy maintenance and accessibility. These devices generated larger bubbles and sacrificed substantial transfer efficiency for maintenance ease. With the emphasis on more energy efficient aeration systems in the 1970's, the technology turned to fine bubble systems. Emphasis on fine pore diffusion has lead to many extensive research programs aimed at the evaluation of design, operation, and control processes relative to improving overall system performance.

Fundamentals of Lagoon Aeration...

For years wastewater lagoon systems have provided secondary treatment performance to many small to medium sized communities. The attributes of these processes have been attractive as cost effective options for the treatment of municipal wastewater. The aeration segment in these systems is the most critical component and is the core of their biological treatment process.

A lagoon systems ability to aerate the incoming sewage has a direct impact on the level of wastewater treatment it achieves. This page will focus on the heart and soul of these systems - aeration.

An ample oxygen supply in a wastewater pond system is the key to rapid and effective wastewater treatment. Oxygen is

needed by the bacteria to allow their respiration reactions to proceed rapidly. The oxygen is combined by the bacteria

with carbon to form carbon dioxide. Without sufficient oxygen being present, bacteria are not able to quickly biodegrade

the incoming organic matter. In the absence of dissolved oxygen, degradation must occur under septic conditions which are slow, odorous and yield incomplete conversions of pollutants. Under septic conditions, some of the carbon will be react

with hydrogen and sulfur to form sulfuric acid and methane. Other carbon will be converted to organic acids that create

low pH conditions in the ponds and make the water more difficult to treat. For example, treated ponds designed to

biodegrade wastewater pollutants without oxygen often must hold the incoming sewage for six months or longer to achieve acceptable levels of pollution removal. This is because the biodegradation of organic matter in the absence of oxygen

is a very slow kinetic process.

The designers of wastewater lagoon systems must take into account the fate of the biological cells, called sludges, that would eventually settle to the pond's bottom. One advantage to using system to treat wastewater is the lack of sludge

volumes that require treatment. Unlike conventional wastewater treatment plants that must remove excess sludges daily,

a pond type system can go from ten to twenty years without ever needing cleaning. This is because, in the presence of sufficient oxygen, bacterial cells that settle to the ponds bottom are eventually biodegraded into carbon dioxide and

inert materials. Since a large portion of municipal wastewater consists of biodegradable organic carbon matter, much of

the settled sludge in the lagoon can be quickly decomposed by the remaining active bacteria. If sufficient oxygen is not present in the ponds, the sludge layer will accumulate faster than it can be biodegraded. When this occurs, the sludges

may build up to a point that it must be removed at a faster rate than would be expected for a pond. This effectively eliminates the main advantage of a lagoon system which is supposed to be an infrequent sludge removal need.

Adequate aeration is also an important element in keeping the lagoons content mixed and in suspension. Even in a partially-mixed hydraulic regime, mixing is very important to the overall treatment process. With adequate mixing,

incoming pollutants and wastewater are better distributed throughout the entire lagoon volume. This results in more

uniform and efficient treatment. In addition, solids that settle can be re-suspended by the aerator's mixing action

and brought back into contact with the microbial population floating throughout the pond. Poor mixing has the effect

of creating thick solids deposits that fall to the lagoon floor before proper treatment has occurred. This causes

improperly treated solids to fall away from the active, overhead treatment process. It also creates septic conditions

on the lagoon bottom which, in themselves, pull available oxygen out of the upper layers of the pond and reduce the effectiveness of treatment in the upper zone.

Clearly the proper aeration and mixing of a lagoon is critical if the system is to properly treat the influent wastewater pollutants. A plant that has never had proper aeration and mixing will often result in a lot of money spent on electrical power for aeration purposes with little lagoon oxygen to show for this expenditure as well as deep accumulations of

partially treated sludge on the lagoons floors which requires frequent removal.

The proper oxygenation of a treatment system also has important implications for an emerging wastewater treatment plant toxicity issue. Raw sewage contains large amounts of ammonia ( NH 3 ). The typical ammonia concentration of

raw sewage is 30 ppm. This ammonia is present as a natural consequence of the degradation of protein-based compounds in wastewater. Nitrogen is a major building block of protein which is present in wastewater due to the discharge of protein based wastewater materials. As the organic compounds that contain protein are degraded, ammonia is released into the raw sewage stream. This is problematic because ammonia has been found to be toxic to aquatic organisms in the water body. In

the presence of adequate oxygen, the nitrogen in ammonia can combine with the oxygen to form non-toxic nitrate compounds

( NO 3 - ). In order for this reaction to occur, the plant must have sufficient dissolved oxygen available.

Both coarse and fine bubble diffused aeration systems transfer oxygen into the water by creating small bubbles. As the bubbles travel through the water, oxygen is transferred across the bubble's surface and into the water. Mechanical

aerators work in the opposite way by creating small droplets of water using a mixer. These droplets are propelled through

the atmosphere above the ponds surface. Oxygen in the air is transferred into the small water droplets which then fall

back into the water.

Factors to Consider...

There are many factors that will act to hinder the transfer of the oxygen load in a wastewater lagoon system. All of

these factors must be considered to ensure that sufficient air is added to allow the necessary pounds of oxygen per

day to be transferred. Some of these factors include :

- The alpha factor in oxygen transfer relates how well oxygen will diffuse into wastewater as compared to clean tap water. This is an important consideration because most aeration equipment is tested and rated in clean water laboratory testing

and these results must be correlated to actual wastewater applications. An alpha factor of 0.80 is common for fine bubble aeration in wastewater lagoons.

- The beta factor in oxygen transfer considers how dissolved solids in the wastewater will hinder the diffusion of

oxygen as compared to being in clean water with few dissolved solids. This is an important consideration because aeration

equipment is usually tested and rated in clean water. A typical beta factor of 0.95 is common for most wastewater applications.

- The theta factor in oxygen transfer relates how temperature changes will affect the rate at which oxygen can be

transferred into the water. This is important because most aeration equipment is sized and rated at standard temperature conditions of 20 degrees Celsius. It must then be adjusted using the theta factor for the expected worst case field temperature conditions. Typically, a theta factor of 1.024 is used and the hottest temperatures of the year are considered since it is more difficult to transfer oxygen into hot water than cold water.

Correction factors for oxygen transfer ( In Turkish  ).

).

- Biological activity in the ponds is optimized when a minimum dissolved oxygen saturation concentration of 2.0 ppm is maintained at all times. The aeration equipment should be sized for this basis.

- The atmospheric pressure at the treatment plant site is an important factor in determining how much oxygen can be transferred. It is more difficult to transfer oxygen at higher elevations than at sea level because of changes in the

local air pressure.

- The maximum allowable oxygen saturation concentration that can occur at the field temperature and lagoon depth conditions must be considered. The maximum amount of oxygen that water can hold at 20 degrees Celsius is 9.09 ppm. As the water temperature increases in the summer months, lesser concentrations of oxygen can be held by the warmer water.

All of the above factors must be considered collectively to properly size aeration equipment for any treatment system.

These factors can be mathematically related to match the actual oxygen requirement (AOR) needed to meet field conditions

with the standard oxygen requirements (SOR) at which aeration equipment is rated in the laboratory. The relationship

between AOR and SOR is very important in properly designing a pond's aeration system. AOR represents the actual amount of oxygen that needs to be added to the ponds under full design loading, full ammonia conversion, and worst case temperature conditions. SOR represents the excess oxygen that must be added in order to make sure that the AOR will be met. Blowers

and diffusers are sized on the basis of SOR which represents clean water conditions at 20 degrees Celsius and sea level

air pressures. They are purchased on the basis of SOR after first relating the required AOR conditions to SOR conditions.

Having determined the standard oxygen requirement of a pond system, it is next important to consider how much air volume

in SCFM (standard cubic feet per minute) will be needed to deliver that mass of oxygen. Each cubic foot of air added to

the lagoon will contain about 0.0173 pounds of oxygen. The oxygen transfer efficiency (OTE) of a diffuser system is a function of its depth in the ponds. Typically, an OTE of about 1.6% per foot of depth is found for fine bubble diffusers

in a pond setting. For a lagoon with ten feet of depth, a transfer efficiency of about 16% could be expected. This means

that 16% of the air added at a depth of ten feet will actively be transferred into the water while eighty-four percent

will be excess and will bubble to the surface. This seems like an excessive air loss rate, but it is the best now available with current technology.

Would your wastewater treatment plant benefit by replacing an older aeration system such as coarse bubble diffusion with

fine bubble technology ? It's well worth investigating. It is important to understand some critical terms, such as oxygen transfer efficiency and alpha, before beginning your evaluation. The oxygen transfer efficiency of an aeration system is

the ratio of the amount of oxygen that actually dissolves into the water to the total amount of oxygen pumped into the

water. Only the dissolved oxygen is available for treatment, and any portion of oxygen that does not dissolve is a waste

of energy and, therefore, money. Finally, aeration basin and aerator layout geometry can dramatically alter oxygen transfer efficiency. Standard clean water transfer efficiency tests are usually based on full floor aerator coverage. This creates a nearly ideal situation for oxygen transfer.

A turbulent counter-current flow regime is established with a volume of water being dragged upward with the rising bubbles, being opposed by an equal flow of water traveling downward. In large basins, such as lagoons, full floor coverage is not normally needed to meet the biological aeration demands. As a result of incomplete coverage, large scale currents can form

a spiral roll in the basins. The air bubbles flow with the water, which significantly reduces the transfer efficiency. Compared with the full floor configuration, many more air bubbles short-circuit their way to the top of the aeration basin.

Although it may be true that fine bubble systems can provide an appreciable savings in many situations, those who purchase and operate these systems without verification do so at the peril of their own bottom line cost. How can you avoid this pitfall? First, test the system proposed with your wastewater. Do not trust a vendor who does not recommend oxygen transfer testing. Second, make sure that oxygen transfer testing mimics the actual conditions, including the configuration of your basin. The cost of aeration system testing can be high and may not be affordable for many plants. Before testing, the potential cost savings of switching to fine bubble aeration should be evaluated. Literature, vender, and EPA values for oxygen transfer efficiently and alpha can be used. Find plants with similar wastewater to refine from their experiences

the values and contact plants to learn from their experience. If the investment in fine bubble diffusion appears favorable, consider testing before replacing the system.

Whether it be a plant upgrade or a new facility, a lagoon system will not work well without proper aeration. As sludge disposal regulations become stricter and disposal sites become scarce, proper aeration will reduce the amount of solids

that may have to be removed from the lagoons since more of the incoming pollutants will be oxidized.

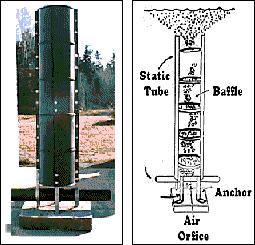

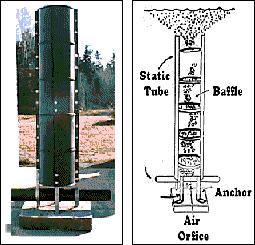

Lagoon Aeration - Coarse Bubble Static Tubes...

All aeration systems try to dissolve oxygen into the wastewater by creating bubbles that contain oxygen. As the bubbles

move through the water, air and oxygen will diffuse into the bulk liquid by transferring across the bubbles surface.

Coarse bubble static tubes create bubbles ( photo of coarse bubble aeration pattern to the left ) by pushing air through

a series of baffles that break up the air flow into bubbles. The bubbles are then ejected into the water at the top of

the tubes. From this point, they flow upward to the ponds surface. Along this critical path, the air in the bubbles must diffuse into the ponds liquid. Once the bubbles reach the ponds surface, it will be to late to transfer oxygen and all

of the remaining air will be lost to the atmosphere.

The static tube style aerator is shown to the below. The design of this system is inherently flawed because the air is released into the water several feet off the lagoon floor. This means that no aeration can occur in the lower half of the lagoons depth. Sludge deposits that build up in this zone have no hope of ever being re-suspended. They simply sit on the bottom and slowly decay under septic conditions. This leads to an even greater depletion of oxygen from the overlying

lagoons liquid layer.

This design is further flawed in shallow lagoons given the fact that oxygen transfer efficiency in a lagoon increases with every foot of depth. A lagoon with ten feet of depth would be losing half of its potential oxygen transfer efficiency by virtue of the fact that the diffusers sit so far off the floor. With coarse bubble aeration, maximum oxygen transfer efficiency (OTE) of 0.75% per foot of depth can be expected. This means that the OTE of a ten foot deep lagoon would be

7.5% if the air was released at the lagoon's bottom. However, only half of this efficiency, perhaps about 4% OTE, is

realized since the air is discharged half way up the pond's depth. Put another way, this same ten foot deep lagoon could transfer twice as much air into the lagoon if the coarse bubble diffusers were closer to the pond's floor. As will be discussed further, this efficiency could be further increased by creating fine bubbles instead of coarse bubbles.

For more information on the use of coarse bubble aeration one may consult the Water Pollution Control Federation's

Manual of Practice FD - 13 entitled "Aeration".

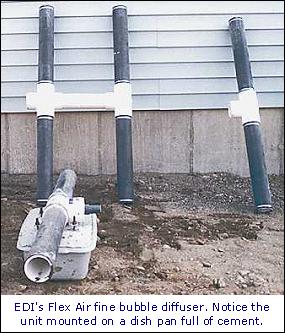

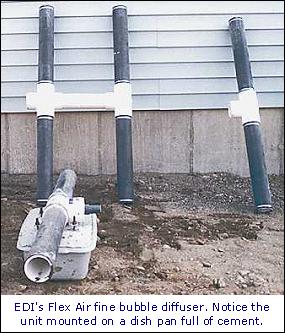

Fine Bubble Aeration...

The use of diffused aeration generally comes down to a choice of using coarse bubble versus fine bubble diffusers. Originally, most diffused air systems used fine bubbles created with porous type media such as ceramic plates. These

systems were prone to plugging and fell out of favor over twenty years ago in lieu of coarse bubble diffusers. The

coarse diffusers systems are less prone to plug because they push the air mass out through large orifices. Their

primary disadvantage is the loss of efficiency that is inherent in using large versus small bubbles.

If a given volume of air is broken into large bubbles, while an equal amount of air is broken into small bubbles, the

smaller bubbles will create a greater opportunity for oxygen to transfer into the water. This is because the smaller

bubbles will contain the same volume of air in a greater number of air bubbles. As the number of bubbles increase, so

does the available surface area over which air can be transferred into water. Fine bubbles are much more efficient at transferring air because they create a larger transfer surface area per unit volume of added air. While coarse bubble diffusion efficiency may have an OTE of 0.75% per foot of pond depth, fine bubble systems may have an OTE of up to 2%

per foot. This means that twice as much air can be transferred from the same air volume using fine bubbles as could

occur using coarse bubbles. As operators look to optimize their plants and streamline costs, many turn to fine bubble technology. Compared to many older systems, fine bubble aeration can reduce the power required to transfer oxygen (and

its associated costs) by up to 50 percent.

For more information on the use of fine bubble aeration one may consult the Water Pollution Control Federation's

Manual of Practice FD - 13 entitled "Aeration".

Mechanical Mixers ( Floating Aerators )...

Major mechanical aerator applications include various activated sludge process modifications such as oxidation ditches and aerated lagoons. Certain requirements are more important for particular applications. Sludge suspension and it's associated mixing requirements in the activated sludge process is usually satisfied when the aerators are selected on the basis of oxygen transfer. For aerated lagoons sludge suspension and the associated mixing usually determine aeration equipment size selection.

Mechanical Mixers ( Floating Aerators )...

Major mechanical aerator applications include various activated sludge process modifications such as oxidation ditches and aerated lagoons. Certain requirements are more important for particular applications. Sludge suspension and it's associated mixing requirements in the activated sludge process is usually satisfied when the aerators are selected on the basis of oxygen transfer. For aerated lagoons sludge suspension and the associated mixing usually determine aeration equipment size selection.

Motor driven, mechanical aerators provide a combination of liquid aeration and mixing. Some mechanical aerators produce the gas - liquid interface by entraining air from the atmosphere and dispersing it into bubbles. Other types disperse liquid in the form of droplets or they produce jets or thin films that contact the ambient air. Some other types even generate both liquid droplets and air bubbles.

Mechanical aerators are usually divided into two major groups : aerators with a vertical axis and aerators with a

horizontal axis. Both groups are further divided into surface and submerged aerators. Some of the factors to consider

about mechanical aeration include the geometric and dynamic parameters, and composition and temperature of the process

water. For more information on the use of mechanical aerators one may consult the Water Pollution Control Federation's

Manual of Practice FD - 13 entitled "Aeration".

Choosing the Right Aeration System...

Will Fine Bubble Aeration Systems Work for You ?...

Activated sludge aeration systems consume from 50 percent to 90 percent of the energy used at most wastewater treatment plants, according to the U.S. EPA. A significant component of operation and maintenance costs, aeration systems have an

equal effect on plant performance and capacity. Many wastewater treatment facilities worldwide operate inefficient and expensive aeration systems. As operators look to optimize their plants and streamline costs, many turn to fine bubble technology. Compared to many older systems, fine bubble aeration can reduce the power required to transfer oxygen (and

its associated costs) by up to 50 percent.

Would your wastewater treatment plant benefit by replacing an older aeration system such as coarse bubble diffusion

with fine bubble technology? It's well worth investigating. It is important to understand some critical terms, such

as oxygen transfer efficiency and alpha, before beginning your evaluation. The oxygen transfer efficiency of an aeration system is the ratio of the amount of oxygen that actually dissolves into the water to the total amount of oxygen pumped

into the water. Only the dissolved oxygen is available for treatment, and any portion of oxygen that does not dissolve

is a waste of energy and, therefore, money.

For clean water aeration, the oxygen transfer efficiency provided by fine bubble diffusers usually exceeds that

available from coarse bubble systems. In wastewater, this may not always be the case. The design engineer and

equipment vendor use a factor called alpha to adjust the clean water transfer efficiency to take into account the

affects of wastewater characteristics on transfer efficiency. Alpha is the ratio of oxygen transfer in a generic

wastewater to oxygen transfer in clean water. The clean water transfer efficiency multiplied by alpha yields the

wastewater transfer efficiency. When evaluating your system, keep in mind that the use of generic or assumed values

can pose problems. Your wastewater may not behave like the assumed generic wastewater. Many factors affect oxygen

transfer efficiencies, alpha values, and ultimately the performance of one aerator versus another. The following

are some issues to consider and understand when evaluating aeration systems.

- The bubble size affects the oxygen transfer efficiency. Smaller bubbles have more surface area per unit volume.

This provides more area through which oxygen can diffuse and thereby increase overall transfer efficiency. Visualize

a basketball filled with ping pong balls. Both take up the same volume, but the ping pong balls have a much greater cumulative surface area. Also, since fine bubbles provide larger total surface area, they create more friction and

rise slower than coarse bubbles. The combination of more transfer area and a greater contact time enhances transfer efficiency.

- Surface active agents (surfactants), such as detergents, lower alpha and the oxygen transfer efficiency. By altering

the surface tension, they often cause fine bubbles to coalesce into fewer, larger bubbles. In addition, the thin film

of detergent molecules between the air bubble and the wastewater can act as a barrier, increasing resistance to oxygen transfer.

- Fouling decreases transfer efficiency. Most fine bubble systems being installed today use a diffuser made of a

flexible synthetic membrane with many small slits or a ceramic disk with very fine holes. Both provide attractive

sites for microbial growth and precipitation of inorganic compounds. This type of fouling can cause bubbles to

coalesce, thereby decreasing the overall transfer efficiency.

- Finally, aeration basin and aerator layout geometry can dramatically alter oxygen transfer efficiency. Standard clean

water transfer efficiency tests are usually based on full floor aerator coverage. This creates a nearly ideal situation

for oxygen transfer. A turbulent counter-current flow regime is established with a volume of water being dragged upward

with the rising bubbles, being opposed by an equal flow of water traveling downward. In large basins, such as lagoons,

full floor coverage is not normally needed to meet the biological aeration demands. As a result of incomplete coverage,

large scale currents can form a spiral roll in the basins. The air bubbles flow with the water, which significantly

reduces the transfer efficiency. Compared with the full floor configuration, many more air bubbles short-circuit their

way to the top of the aeration basin.

Although it may be true that fine bubble systems can provide an appreciable savings in many situations, those who

purchase and operate these systems without verification do so at the peril of their own bottom line cost. How can

you avoid this pitfall ? First, test the system proposed with your wastewater. Do not trust a vendor who does not

recommend oxygen transfer testing. Second, make sure that oxygen transfer testing mimics the actual conditions,

including the configuration of your basin. The cost of aeration system testing can be high and may not be affordable

for many plants. Before testing, the potential cost savings of switching to fine bubble aeration should be evaluated. Literature, vender, and EPA values for oxygen transfer efficiently and alpha can be used. Find plants with similar

wastewater to refine from their experiences the values and contact plants to learn from their experience. If the

investment in fine bubble diffusion appears favorable, consider testing before replacing the system.

).

).