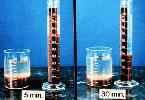

Slow settling in test...

"Settleometer"...

"Settleometer"...

"Settleability Test"...

"Settleability Test"...

"Settleability Test for Bulking Sludge"...

"Settleability Test for Bulking Sludge"...

"Protozoa"...

"Protozoa"...

"Rotifer"...

"Rotifer"...

"Filamentous Bacteria"...

"Filamentous Bacteria"...

"Euglypha sp. - 1"...

"Euglypha sp. - 1"...

"Euglypha sp. - 2"...

"Euglypha sp. - 2"...

"Euglypha sp. - 3"...

"Euglypha sp. - 3"...

| Activated sludge - centrifuge test benchsheet |

| Date : ____________ Time : ____________ Analyst : ____________ |

| Sample location : _________________________________________ |

| Sample characteristics : ___________________________________ |

| ( 1 ) | ( 2 ) | ( 3 ) | ( 4 ) |

| Sludge source | Depth in mm of entire sample in centrifuge tube |

Depth in mm of solids after centrifugation |

Percent solids [ ( 100 ) ( 3 / 2 ) ] |

| ATC | _______________________ | _______________________ | _______________________ |

| RSC | _______________________ | _______________________ | _______________________ |

| WSC | _______________________ | _______________________ | _______________________ |