Selection of Wastewater Management Technologies...

This chapter discusses alternative wastewater management technologies and determines the most suitable method for collection,

treatment and disposal of the treated wastewater for this plan.

Wastewater Collection Technologies...

Wastewater collection technologies reviewed for this study include gravity sewers, force mains, vacuum sewers, small

diameter effluent sewers, STEP pressure sewer systems, and grinder pump pressure sewer systems. Wastewater collection and

conveyance can often account for 60 - 80 % of the total cost of a wastewater management system.

Gravity Sewers...

The conventional gravity sewer has historically been the most popular method used for the collection and conveyance of

wastewater. The pipes are installed on a slope to enable the wastewater to flow by gravity from the house site to the

treatment facility. Pipes are generally 8 inches and larger and they typically are installed at a minimum depth with 3

feet of earth cover and a maximum depth of about 25 feet. Manholes are located a maximum of 400 feet apart or at changes

of direction or slope. Most manholes today are manufactured of precast concrete with watertight rubber seals.

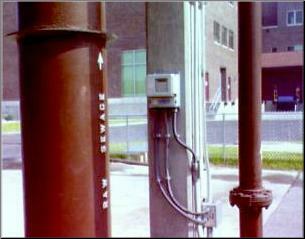

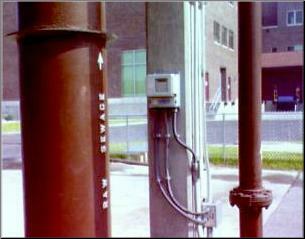

Force Main with Standard Pump Station (Pressure Sewer)...

A traditional pressure system involving pump stations and force mains are used in conjunction with gravity sewers and are

typical in areas where topographical constraints, excessively high water tables, or geological instability prevents

installation of gravity sewers. Pumps are employed to pump sewerage across watershed boundaries. Pump stations are located

in the low spots of watersheds to collect sewerage flowing in gravity sewers. The sewerage is collected in wet wells and

upon reaching a certain design volume are pumped through force mains to either another gravity sewer or into the treatment

plant. The sewer profile of the force mains usually parallels the ground surface profile. Cleanouts are used in force mains

to provide access for flushing. Automatic air release valves are required at or slightly downstream of summits in the force

main profile. Because of potential odors from the pump stations, odor control is recommended. The pump stations have higher

operation and maintenance costs than other types of systems. To justify the use of this type of system, typically flows to

the pump stations need to be greater than 100,000 gpd. These flows will serve a minimum of approximately 400 households.

Grinder Pump Pressure Sewers...

A grinder pump (GP) pressure sewer has a pump at each service connection. The pumps are usually small (approximately one

horsepower). The GP is equipped with a grinding mechanism that macerates the solids. The pumps discharge into a pressurized

pipe system terminating at a treatment plant or gravity sewer. The pressure sewers from the GP will not experience any

infiltration. However, infiltration and inflow can occur from the laterals that extend from the house to the GP well and

must be prevented. Because of the small diameters, curvilinear horizontal alignment, and profile paralleling the ground

surface, excavation depths and volumes are typically much smaller for a GP pressure sewer than for conventional sewers.

GP’s best serve areas where it’s difficult to construct a gravity sewer. Cost comparisons between areas served

by GP systems and areas served by conventional gravity systems with a pump station indicate that GP systems and can cost

significantly less to construct and maintain.

Small Diameter Effluent Sewers...

A small diameter effluent sewer (SDES) is used in conjunction with septic tanks. The septic tank effluent is transported by

gravity to a conventional sewer systems or to a treatment plant. Both the horizontal and vertical alignments of the pipes

can be curvilinear. Uphill sections can be used, provided that there is enough elevation head upstream to maintain flow in

the desired direction, and that there is no backflow into any service connection. Minimum diameters can be four inches.

Plastic pipe is typically used; it is economical in small sizes, and it resists corrosion by the septic wastewater.

Cleanouts are used to provide access for flushing. Manholes are used infrequently. Air release risers are required at,

or slightly downstream of, summits in the sewer profile. Odor control is important at all access points since the SDES

carries odorous septic tank effluent. Because of the small diameters and flexible slope and alignment of the SDES,

excavation depths and volumes are typically much smaller than with conventional sewers. Two varieties of SDES systems

have been used: the variable grade effluent sewer (VGES) and the minimum grade effluent sewer (MGES). The VGES allows

flexibility of horizontal and vertical alignment, provided that there is enough elevation head to maintain flow in the

desired direction and that there is no backflow into any service connection at design flow. In the MGES, minimum downward

slopes are imposed.

Septic Tank Effluent Pump Pressure Sewer (STEP)...

A septic tank effluent pump (STEP) pressure sewer has a septic tank and a pump at each service connection. The pumps

discharge septic tank effluent into a completely pressurized pipe system terminating at a treatment plant or a gravity

sewer. Because the mains are pressurized, there will be no infiltration into them, but infiltration and inflow into the

house sewers and the septic tanks can occur. The pumps, which can be installed in the septic tank or in a separate well,

typically are 1/3 to 1/2 horsepower (0.25 to 0.37 kW) and require 110 - 120 volts. They are designed to pump septic tank

effluent, but will not pump raw sewage solids. The head and flow rate provided by the pumps are generally about 50 feet

and 15 gallons per minute (gpm) but vary widely. The discharge line from the pump is equipped with at least one check valve

and one gate valve. The sewer profile normally parallels the ground surface profile, and the horizontal alignment can be

curvilinear. The pipes are usually installed slightly below the frost line. Plastic pipe is generally used - it is economical

in small sizes, and it resists corrosion by the septic wastewater. The minimum diameter is typically 1-1/4 inch for service

connections and the smallest mains. Cleanouts are used to provide access for flushing, and automatic air release valves are

required at or slightly downstream of summits in the sewer profile. Odor control is needed at all access points since the

sewers carry septic tank effluent. Because of the small diameters, curvilinear horizontal alignment, and profile paralleling

the ground surface, excavation depths and volumes are usually much smaller for a STEP pressure sewer than for conventional

sewers. The maintenance associated with STEP systems, to avoid clogging of the system, includes pumping of the septic tank

on a regular and frequent basis. If this is not done, the pump will plug with solids.

Vacuum Sewers...

A vacuum sewer system has three major subsystems: the central collection station, the collection network, and the on-site

facilities. Vacuum is generated at the central collection station and is transmitted by the collection network throughout

the area being served. Sewage from conventional plumbing fixtures flows by gravity to an on-site holding tank. When about

10 gallons of sewage has been collected, the vacuum interface valve, which operates automatically using pneumatic controls,

opens for a few seconds allowing the sewage and a volume of air to be sucked through the service pipe and into the main. The

difference between the atmospheric pressure behind the sewage and the vacuum ahead provides the primary propulsive force.

The fact that both air and sewage flow simultaneously produces high velocities and prevents blockages. Following the valve

closure, the system returns to equilibrium and the sewage comes to rest at the low points of the collection network. After

several valve cycles, the sewage reaches the central collection tank, which is under vacuum. When the sewage in the central

collection tanks reaches a certain level, a conventional non-clog sewage pump discharges it through a force main to a

treatment plant or gravity interceptor.

"Definition Sketch for Chemical and Biological Treatment"...

"Definition Sketch for Chemical and Biological Treatment"...

Wastewater Treatment Technologies...

Septic Systems...

Septic systems include tanks and disposal fields. Septic tanks are buried, water-tight, corrosion resistant containers

designed to receive and attenuate raw wastewater in order to separate solids from the liquid, remove grit and grease,

provide limited digestion of organic matter, accumulate settled solids, and allow the clarified liquid to discharge for

disposal. In general, septic tanks are designed to detain the peak flow for 24 hours. Septic tanks can be of various sizes

with single family tank volumes of approximately 1,000 gallons (depending on the house size) and communal tanks as large as

needed. Single-compartment septic tanks have performed well, but two-compartment septic tanks increase the efficiency of

retaining solids and are required in the State of Delaware. Screens with outlet orifices have also shown reduced solids

discharge. A septic system performs two levels of treatment of wastewater. First, the wastewater enters a septic tank where

solids are settled from the water. The water leaving the tank still has dissolved pollutants and a minor amount of fine,

dispersed particles. This partially treated wastewater is then directed to a drain field pipe system. The pipe is perforated

to allow the water to soak into the soil and finally to the groundwater. In the soil near the pipe, much further renovation

of the water is accomplished. Bacteria feeds upon and cleans the water, and the soil filters the water. This results in a

"mat" of bacteria created near the piping.

Functional septic systems have a negligible impact on the groundwater quality in rural settings due to the dilution effect

of the groundwater. However, septic systems are not suitable as a long-term solution for suburban development. A septic tank

does not have to fail to create a negative impact on groundwater quality. Their density creates the problem. Contamination

of the groundwater from nitrogen loading is the main concern with respect to functional septic systems. When residential

areas with septic systems are more densely developed, the pollution effect of the nitrogen reaching the groundwater is not

mitigated by dilution. The primary drinking water standard for nitrate nitrogen is 10 mg / L. Above that level there is a risk

of contracting methemoglobinemia (or "blue baby" syndrome). The drainfield below the septic tank, even for a well

operating system, produces a range of 9 to 125 mg / L of total nitrogen with a mean of 45 mg / L. All septic systems have a

finite life. Based on historical usage, it can be expected that eventually all septic systems will fail and not all can be

repaired. Failure of a septic system can either be a backup into the house or some type of leak that can go undetected

indefinitely. The major disadvantage of failing septic systems that are still in use is that various types of bacteria and

viruses can severely contaminate the groundwater and impact the potable water supply.

Prior to installing a septic system, a permit must be obtained from DNREC. The permit states that if a regional system is

available at a later date, the applicant should disconnect from the septic system and tie into the regional system. Currently

in NCC, replacement of failing septic systems and connection to regional sewer systems costs the taxpayer's approximately

$ 15,000 per house. This is just for the local collector sewer, with no allowance for a share of the transmission and treatment

systems. Since 1969, NCC has been involved with nearly 100 septic elimination projects. These range from single family homes

to entire subdivisions. The total cost of these projects is approximately $ 24.1 million. From 1996 to 1998, DNREC recorded

over 208 septic failures in NCC of which some 24 were located in the SSSA.

Lagoons...

In a typical lagoon treatment system a series of lagoons (or ponds) are placed to treat expected ranges of domestic

wastewater. The number of lagoons can vary as can this size. When used for treatment before spray irrigation, the first

lagoons provide biological treatment of the wastewater and a final lagoon provides storage. All lagoons are lined with an

impermeable barrier to prevent wastewater from infiltrating into the groundwater. There are several types of wastewater

lagoon systems pertinent to domestic wastewater treatment including facultative, aerated, or a combination of the two.

Lagoons utilize a combination of anaerobic processes and aerobic processes. Ponds can be aerated with mechanical devices

or aerated by natural processes such as wind turbulence and photosynthetic activity. The type of lagoon system chosen as

an alternative depends on land availability, flow characteristics, effluent requirements and the characteristics of the

wastewater. Facultative lagoons are usually greater than 4 feet deep with an aerobic layer overlying an anaerobic layer.

Solids settle to the bottom as sludge deposits. The usual hydraulic detention time is 5 to 30 days for treatment. Separation

of settled solids and anaerobic digestion of the settled solids occur along with reduction of BOD5 and pathogen

concentrations. Facultative lagoons usually require more land area and have variable effluent quality.

Aerated lagoons are usually deeper with detention times of 3 to 10 days for treatment. The major advantage of aerated

lagoons is that they require less area and there are minimal odors. A feature of the aerated lagoons is that oxygen supply

is enhanced by mechanical aerators. Two types of aerated lagoon systems are used including; "completely mixed" and

"facultative aerated". The completely mixed aerated lagoon system refers to all settleable solids being completely

suspended. The facultative aerated lagoon system, also called partially mixed, does not suspend all of the settleable solids.

Power requirements will vary for the completely mixed lagoon system based on the concentration of the mix, lagoon geometry

and the size and type of aerators used. The polishing / storage lagoon can vary in depth and has a detention time of 30 to

50 days for storage during inclement weather. These lagoons are protected from fluctuating water levels and wave action by

rock or vegetation. The wastewater in the storage lagoon can be further polished to increase the treatment levels and the

effluent water quality.

The main advantage to using lagoon systems is their simplicity of treatment. Lagoons treat wastewater over an extended

period of time and can be designed to completely degrade sludges. They are not as susceptible to "shock" loading.

For example, should a toxic chemical or other type of slug load be introduced into the lagoon system, the constituent is

diluted and can be isolated. The regular wastewater can be bypassed to the next lagoon for continued treatment. Lagoon

systems also equalize peak inflows. Lagoon systems have low operation and maintenance costs since fewer staff and less

mechanical equipment are needed to operate this type of system. Minimal sludge is produced which reduces capital and

operational costs associated with sludge stabilization, conditioning, dewatering and disposal. A disadvantage of lagoon

systems is that they require more land than mechanical wastewater treatment facilities.

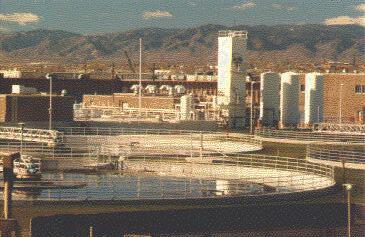

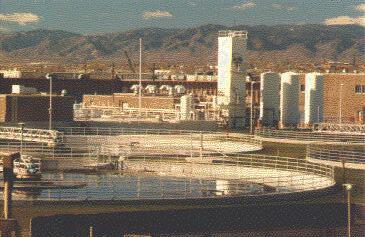

Activated Sludge...

The activated sludge process is an aerobic biological system that utilizes a microbial population to oxidize and breakdown

the organic matter in the wastewater. The process consists of aeration tanks followed by clarifiers that separates the

treated liquid from the biological solids. Biomass is recycled from the clarifier into the aeration tank to maintain high

bacterial concentrations that aid in the treatment. Sludge generated from the process must be digested, dewatered, and

transported to a disposal site. Often, chemical addition is included and operational parameters must be strictly met to

allow for efficient treatment. The advantage of an activated sludge treatment system is that it requires a small area for

the treatment process because it uses shorter treatment durations than lagoon systems. A disadvantage of this type of

system is that it produces large quantities of sludge that require dewatering and disposal. Because of the short treatment

durations, when an unexpected toxic is introduced, the entire system may suffer and effluent quality degrade. The activated

sludge treatment system requires higher operation and maintenance costs associated with the chemical and mechanical features.

Additional Wastewater Technologies...

Filtration Systems...

Filters are often used to "polish" effluent from the treatment processes described above. A filter can be a

gravity or pressure filtration system that is capable of producing a high quality effluent. It can be both a biological

and / or a physical treatment technology that consists of a bed of granular material, usually sand, through which effluent

from an aerobic unit, septic tank, package treatment unit or lagoon flows. The surface is allowed to drain between wastewater

applications for intermittent gravity filters but is constantly inundated over a period of time with rapid or upflow filtration.

Accumulations of solids are periodically removed from filters that are accessible and additional sand is added as necessary

to insure adequate filtration. Subsurface intermittent sand filters are non-accessible types with larger surface area and

are not cleaned without excavation of the filter. Delaware regulations require that filtration be used on effluents prior

to residential spray irrigation or irrigation of food crops. The benefit of filtration is that it provides an additional

level of treatment that screens out any suspended solids that exist in the effluent. These remaining small particles can

be pathogens, adsorbed metals, or inorganic nutrients like phosphorous.

Biological Nutrient Removal...

Biological Nutrient Removal (BNR) is a term usually applied to mechanical treatment plants. It basically relies on microbes

to remove nitrogen and / or phosphorous. This is helpful when the effluent is discharged to a waterway, but if spray

irrigation is used as the disposal method, the nutrient value of the effluent for crops is lost.

Constructed Wetlands : Constructed wetlands can achieve high quality treatment. Wastewater enters a constructed

wetland evenly across its width. The wetland can be constructed such that free water is evident at the surface, amongst

the plantings or such that the water travels through the gravel in which the plants are supported. Impermeable liners on

the sides and bottom conserve water and prevent leakage. The roots of marsh plants form a dense mat. Here chemical,

biological, and physical processes take place which purify the water. Wetlands can receive effluents as polluted as septic

tank effluent and reach very high quality levels. They are also useful in polishing effluents from activated sludge plants ,

and lagoons.

Disinfection...

Wastewater is disinfected to prevent the outbreak of waterborne pathogens. All effluent from

treatment systems receives disinfection prior to disposal. The common disinfectants used are chlorine, ozone and UV

light. For chlorine, the preferred option by NCC is liquid sodium hypochlorite, which is safer than gaseous chlorine.

Dechlorination of the water is usually practiced when the water is discharged to surface waters to prevent any chlorine

from housing aquatic life.

Wastewater Disposal Technologies...

Stream Discharge...

The discharge of properly treated and disinfected wastewater to a surface watercourse is an available disposal technique

often known as "stream discharge". The level of treatment required varies depending on local regulations, stream

water quality requirements or other site - specific conditions. The disadvantage of stream discharge is that there are no

provisions for water reuse. DNREC does not prefer this method of disposal.

Spray Irrigation...

Spray irrigation can be described as a slow rate land application of properly treated and disinfected wastewater on

suitable soils. The soil strata must be suitable for infiltration/percolation and usually contain deep, well drained soils

with mild surface slopes to prevent runoff and erosion. As the wastewater percolates through the ground, the soil matrix

provides additional filtration, absorption, ion exchange and precipitation of the effluent, as well as microbial breakdown

of any remaining organic material. The vegetative cover also provides some evapotranspiration of the treated wastewater,

nutrient uptake, reduction of soil erosion, and maintenance of soil permeability. The selection of vegetative cover plays

a vital role in the nutrient removal efficiency of the system. Extensive nutrient balances are performed to insure that

nitrogen removal efficiencies will meet groundwater requirements. Hay, corn, fruit crops, and lawns all are possible

vegetative covers if managed correctly. The application rates for spraying the effluent is greater for agricultural than

residential practices. Application rates also vary with the type of crop being sprayed. Irrigation equipment can be

categorized as portable or fixed. The selection of irrigation equipment is based on the size of spray fields, agricultural

practices, field conditions (shape, slope, vegetation, and soil type), climate, operating conditions, land use, and

economics.

Wastewater Disposal Technologies...

Stream Discharge...

The discharge of properly treated and disinfected wastewater to a surface watercourse is an available disposal technique

often known as "stream discharge". The level of treatment required varies depending on local regulations, stream

water quality requirements or other site - specific conditions. The disadvantage of stream discharge is that there are no

provisions for water reuse. DNREC does not prefer this method of disposal.

Spray Irrigation...

Spray irrigation can be described as a slow rate land application of properly treated and disinfected wastewater on

suitable soils. The soil strata must be suitable for infiltration/percolation and usually contain deep, well drained soils

with mild surface slopes to prevent runoff and erosion. As the wastewater percolates through the ground, the soil matrix

provides additional filtration, absorption, ion exchange and precipitation of the effluent, as well as microbial breakdown

of any remaining organic material. The vegetative cover also provides some evapotranspiration of the treated wastewater,

nutrient uptake, reduction of soil erosion, and maintenance of soil permeability. The selection of vegetative cover plays

a vital role in the nutrient removal efficiency of the system. Extensive nutrient balances are performed to insure that

nitrogen removal efficiencies will meet groundwater requirements. Hay, corn, fruit crops, and lawns all are possible

vegetative covers if managed correctly. The application rates for spraying the effluent is greater for agricultural than

residential practices. Application rates also vary with the type of crop being sprayed. Irrigation equipment can be

categorized as portable or fixed. The selection of irrigation equipment is based on the size of spray fields, agricultural

practices, field conditions (shape, slope, vegetation, and soil type), climate, operating conditions, land use, and

economics.

The disadvantages of spray irrigation are that it requires a large amount of land and the land application is contingent

on proper weather and site conditions which can be restrictive during wet or extremely cold periods of the year. The

advantages of spray irrigation far outweigh the disadvantages. Spray irrigation is considered the most appropriate way

to dispose of treated wastewater by DNREC because it recharges the groundwater aquifers and provides perennial baseflow

to streams. Spray irrigation recycles nutrients into the soil strata and eliminates the disposal of those nutrients into

the streams. Spray irrigation also preserves large open contiguous parcels of land within the SSSA. Any lands irrigated by

treated effluent are not using fresh groundwater for the irrigation and, therefore, the spray is a benefit by its

offsetting use.

Subsurface Soil Absorption...

Subsurface soil absorption systems are common for on-site or small communal systems with proper site conditions. Subsurface

soil absorption systems dispose of septic tank or aerobic unit effluent. In a conventional gravity system, effluent flows

to perforated distribution piping that has been laid in gravel-filled. The gravel is covered with soil to the original

ground level. From the piping, the liquid drains through the gravel and into the undisturbed soil beneath the trenches.

Finally, the liquid percolates down through the soil strata and into the groundwater. These systems are usually built on

level or moderately sloped ground. Modifications of the standard trench system are implemented when particular soils and

slopes are the constraints. Some of these modified systems are seepage beds, subsurface sand filters, and elevated sand

mounds. Seepage beds are similar to standard trenches, but the entire piped area is excavated. Seepage beds are an alternative

where space is somewhat limited and they require nearly level ground. Subsurface sand filters are similar to seepage beds

except that sand is placed to a minimum depth of 12 inches to replace unsuitable soils. In an elevated sand mound system,

effluent is pumped from a dosing tank to perforated pipe in a sand mound, which covers plowed soil. Liquid flows through

gravel, through sand and into the soil. The mound's vegetation enhances evapotranspiration. Although some natural soil

permeability is required, an elevated sand mound may be placed in areas with a relatively shallow limiting zone, such as

rock or soils with a high water table. Historically, sand mound systems have not worked well in NCC and have been prone to

failure.

Other modifications to the preceding subsurface soil absorption systems include dosing systems, alternating absorption

areas, serial distribution systems, evapotranspiration beds and oversized beds. Dosing systems are trenches or beds, which

receive effluents from a pump or a siphon. This provides an even release of effluents from all points in the pipes.

Distribution boxes are not needed in these systems. Alternating absorption areas are actually two systems in one. One field

is dosed and then rested, then the other is dosed and then rested. They require two distribution boxes and fields are usually

switched every 6 to 12 months. Serial distribution systems apply effluent by pump through absorption trenches, which follow

topographic contours. The trenches are in tiers-one above another. Drop boxes regulate liquid flow so the highest trench

fills first, the second trench fills next, etc. These systems are conducive to severely sloped land.

Evapotranspiration beds are mounds of sand that are lined with an impervious liner into which the effluent is pumped. There

is no percolation to groundwater with this type of system. All of the effluent is evapotranspirated through the soil surface

and cover vegetation. Oversized beds are absorption beds that are sized larger than normal due to low soil percolation rates.

Otherwise, the oversized bed is designed as an absorption bed. Subsurface soil absorption systems are relatively costly and

not suitable for large flow rates. Additionally, nitrogen is not removed from the system since discharge occurs below the

root zone of vegetation, and, therefore, directly enters the groundwater without plant uptake.

Biosolids Management...

Biosolids are the necessary resultant of wastewater treatment. When water is cleaned of its contaminants, they must be

removed in the form of biosolids. These solids take several forms such as septage from septic tanks and sludges from

mechanical treatment plants. Ultimate disposal is a necessary and important consideration in planning.

Dewatering...

Sludges generated at a wastewater treatment facility or removed from existing septic systems contain high water

concentrations. To reduce the volume for disposal, dewatering is required. Some typical mechanical dewatering devices

available include, but aren’t limited to, filter belt presses, vacuum filters, centrifuges, and heat drying. Digested

or stabilized sludges can also be dewatered in drying beds, which require proper climate conditions that promote atmospheric

evaporation. The advantages of mechanical dewatering is that it produces higher solids concentration in sludge in a short

period of time. The disadvantage of mechanical dewatering is that these processes have additional maintenance and operation

costs. They produce solids that must be further handled every day as an ongoing, continuous operation. In larger wastewater

treatment systems, the biosolids management costs can equal or exceed the operational costs of the liquid wastewater

treatment. Odors are managed by complete enclosure of the dewatering processes.

Reed Beds...

Reed beds consist of a sand bed with dense reed vegetation (Phragmites Communis) and an underdrain system. The

underdrain system collects percolated water and pumps it back into the headworks of the WWTP. This technology utilizes

the root system of vegetation to aerate and degrade biological solids. Evapotranspiration also occurs through the reeds

which assists in dewatering. The reeds hollow stalks maintain aerobic conditions within the dewatered sludges as they

accumulate and prevent anaerobic conditions from ensuing which cause odors. The reed system produces a dry, degraded

material that must be removed approximately every 10 years. The advantages of a reed bed system are low operation costs

and maintenance requirements. The disadvantage of a reed bed system are the land requirements, annual harvest of the

vegetative material and the potential trace concentrations of heavy metals in the biosolids that can prevent beneficial

reuse of the biosolids residue. Extra caution must be taken with reed beds to prevent odors.

Water Reuse...

This plan recommends water reuse by irrigating treated wastewater effluent for residential, agricultural and park lands

throughout the SSSA. A network of non-potable distribution piping is planned that will extend throughout the SSSA, and in

general, follow the alignment of the proposed conveyance system. An additional chlorination step may be added to the

treatment process preceding distribution to provide a residual chlorine level in the transmission lines. Monitoring of

the effluent water quality will occur at the treatment plant outfall to insure that the water meets all permit requirements

before entering the distribution system. By distributing the effluent back over the entire SSSA, the County can reduce land

requirements for spray irrigation, recharge aquifers, and reduce groundwater withdrawal for irrigation. Based on geologic

cross sections of southern New Castle County contained in the Phase II - Evaluation of Groundwater Availability

report by the Delaware Geological Survey, irrigation throughout the SSSA will include recharge to the Columbia, Vincetown,

Mt. Laurel and Englishtown aquifers. Preserving the groundwater supply will become extremely important as the SSSA population

grows since water supply from the 5 aquifers continues to become more limited in the SSSA. Treated effluent can be used for

irrigation purposes on golf courses throughout the SSSA. The benefits of reusing the water would include recharging the

groundwater aquifers and reducing groundwater withdrawal by the golf course for irrigation and decorative purposes.

Agreements should be set up with the golf course superintendent to expect operation within defined guidelines since the

irrigation water contains effluent. Such guidelines would include acceptable hydraulic loading rates, storage of the

effluent, application areas, and any other regulatory requirements. Future reuse of the effluent may include decorative

purposes such as fountains and reflection ponds. By using the reclaimed water, the SSSA can limit groundwater withdrawal

for these features.

Technology Selection Criteria...

The selection process is centered on collection and conveyance, treatment and disposal. The biosolids management, water

reuse and other technologies shall be integrated into the final recommended treatment and disposal methods. The criteria

for selecting the appropriate collection and conveyance system includes; odor problems, capital costs, operation and

maintenance costs, dependability, availability, capacity for ultimate build out flows, track record, susceptibility to

clogging and suitability for the SSSA. The criteria for selecting the appropriate treatment system includes; odor problems,

dependability, capital costs, operation and maintenance costs, capacity, track record, environmental effects, land requirements,

ability to react to slug loading, sludge/septage production, aesthetics, regulatory acceptance and suitability for the SSSA.

The criteria for selecting the appropriate disposal system includes supplemental treatment, land requirements, environmental

effects, preservation of open space, aesthetics, dependability, and regulatory acceptance.

Recommended Wastewater Management...

For the SSSA, a combination of gravity sewers and force mains with pump stations is recommended as regional collection

and conveyance system. The regional infrastructure is planned along low areas within the watershed and along roadways.

Wherever possible, the conveyance system was positioned to allow the serviced parcels to access the system by gravity flow

and reduce the overall number of future pump stations to be maintained by NCC. All gravity lines were sized to accommodate

ultimate build out flows at a two-thirds full at capacity. The regional infrastructure was terminated at locations where

the area of contribution was 500,000 gpd. Traditional pump stations with force mains will be required in some areas to lift

the wastewater over watershed boundaries and eventually into the headworks of the proposed treatment plant. All pump stations

will contain biofilters to neutralize any odors from the raw sewage. Future individual connections into the regional

infrastructure are encouraged to investigate pressure sewer technologies that suit the local site conditions.

A lagoon system is recommended to meet treatment needs. This follows the successful lead of Water Farm No. 1 as the best

available technology for the SSSA. Lagoon systems minimize sludge production which lowers capital and operational costs

associated with sludge stabilization, conditioning, dewatering and disposal. Lagoon systems are also cost effective for

construction and operation, and large parcels of land are available in the SSSA to accommodate the land requirements. The

system also provides a large volume of water to buffer and dilute any hazardous materials that may enter the system and

provides flow equalization. Lagoon systems also facilitate future expansion as demand increases, and therefore, can be

constructed in a modular fashion to spread out the capital cost of the infrastructure as the community grows. A final

bonus for the lagoon system is that it can be aesthetically pleasing. A septage receiving station is recommended at the

site of the lagoon treatment plant. Any periodic sludge removed from the lagoons would also be handled in the station. A

reed bed system or a mechanical type receiving station can meet the planning needs and subsequent design will provide for

the better of these alternatives. The reed system produces a dry degraded material that accumulates in the beds and must be

removed approximately every 10 years. Reed bed systems also have low operation costs and maintenance requirements. Since

odors are of concern, a mechanical system placed inside a building may be chosen.

The site conditions in the SSSA favor land application of treated wastewater as the disposal method. Well drained soils,

moderate slopes and large open contiguous parcels provide ideal conditions for spray irrigation. Spray irrigation also

preserves large open tracts of land, which is an important component in the overall selection process. Water reclamation,

either on the spray fields or sent back throughout the SSSA, will help recharge the groundwater and reduce groundwater

withdrawal. This added benefit will help preserve water supply in the SSSA since the area relies solely on groundwater

for its water supply.

"Definition Sketch for Chemical and Biological Treatment"...

"Definition Sketch for Chemical and Biological Treatment"...