01. A : The stabilization of organic matter is accomplished biologically using variety of microorganisms. The microorganisms convert the colloidal and dissolved organic matter into various gases and into protoplasm. Because protoplasm has a specific gravity slightly higher than that of water, it can be removed from the treated liquid by gravity.

02. Q : "The relationship between the source of carbon and the source of energy for microorganism is important." Explain the importance of carbon to microorganism.

02. A : Carbon is the basic building block for cell synthesis. A source of energy must be obtained from outside the cell to enable the synthesis to proceed. The goal of wastewater treatment is to convert the carbon and energy source in the cells of microorganisms, which can be removed by settling. The goal of wastewater treatment is to convert both the carbon and energy in wastewater in the cells of microorganisms, which can be removed by settling.

03. Q : What are the major roles played by "bacteria", "protozoa" and "fungi" in wastewater treatment ?

03. A : Bacteria are responsible for the stabilization of wastes coming into a treatment plant. Many of these bacteria form flock particles, or clusters of bacteria that break down waste. Floc particles also serve as sites on which waste can be adsorbed and broken down later.

Fungi are multicellular, nonphotosynthetic, heterotrophic organisms, which use soluble food. They are obligate that reproduce by variety of methods including fission, budding, and spore formation. Requires only half ofnitrogen as bacteria.

Protozoa are microscopic, unicellular organisms. They are found in large numbers in the activated sludge process. Protozoa perform many beneficial roles in the treatment process, including the clarification of the secondary effluent through the removal of bacteria, the flocculation of suspended material and as bio-indicators of the health of the sludge.

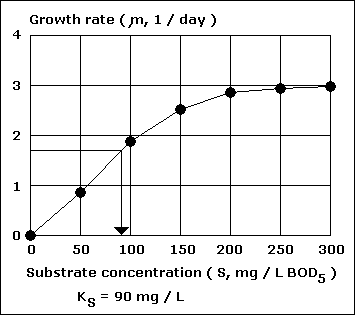

04. Q : Give bellow is growth rate as a function of substrate concentration, determine the "half saturation constant, KS".

04. A :

05. Q : The following are the BOD5 values of two different wastewaters.

| Wastewater | BOD5 ( mg / L ) |

| A | 150 |

| B | 1,500 |

Tell the type of these wastewaters. That is, which is the municipal and which is the industrial wastewater ? Why ?

05. A : A is municipal wastewater B is industrial wastewater.

06. Q : What are the key considerations determining the deployment of "septic tank" system for the treatment of domestic wastewater ?

06. A : A septic tank and tile field can be used only if only when soil conditions are favorable. One method to determine whether or not a tile system can be installed is the soil percolation test. Further limitations include : detention time, distance from surface water, footing drain, or storm drain; ground water table, etc.

07. Q : What is the major role of "secondary treatment" in wastewater treatment operation ? How does "secondary treatment" work ?

07. A : The major role of secondary treatment is to remove the soluble BOD that escapes primary treatment and to provide further removal of suspended solids. Removal of biodegradable organics and suspended solids accomplished by using chemical and / or biological processes : trickling filters, activated sludge, and rotating biological contactors.

08. Q : What is the major function of an "equalization tank" ? When is an "equalization tank" needed ?

08. A : Equalization basin is used to improve the effectiveness of both secondary and advanced WW treatment processes. Since WW flow rate varies from hour to hour, reflecting living habits of the served area, an equalization basin is needed to : smooth out fluctuations in flow rate, to provide more consistent treatment. Done by storing excess wastewater during high flow periods, Wastewater is released during low flow periods. It results in more consistent treatment.

09. Q : Both trickling filter and activated sludge processes are both biological treatment systems. But there is one major "process" difference between them. What is the major process difference between the "trickling filter" and "activated sludge" ?

09. A : The major process difference is that in trickling filters the biomass is steady, in activated sludge process the biomass is in suspension.

10. Q : What is "sludge volume index, SVI" ? What is the utility of SVI in the design and operation of activated sludge process ?

10. A : The SVI is defined as the volume in milliliters occupied by 1 g of activated sludge after aerated liquor has settled 30 min :

SVI = SV ( mL / L ) / MLSS ( g / L ) = ... mL / g

The SVI is a key factor in system design, it limits the reactor basin MLSS concentration and, in turn, the MLVSS concentration that can be achieved, because it controls the settling tank underflow concentration. SVI is an indicator of settling characteristics of sludge and used to control the rate of sludge return to the reactor basin. It can be related to the quantity and solids concentration in the secondary settling tank and can also be used as an indication of settling characteristics of sludge.