Exams for Wastewater Treatment Plant Operators...

Exam - 5...

Treatment & Disposal Technologies...

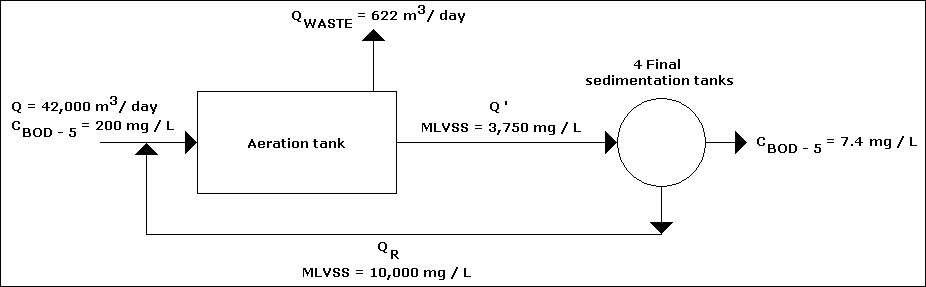

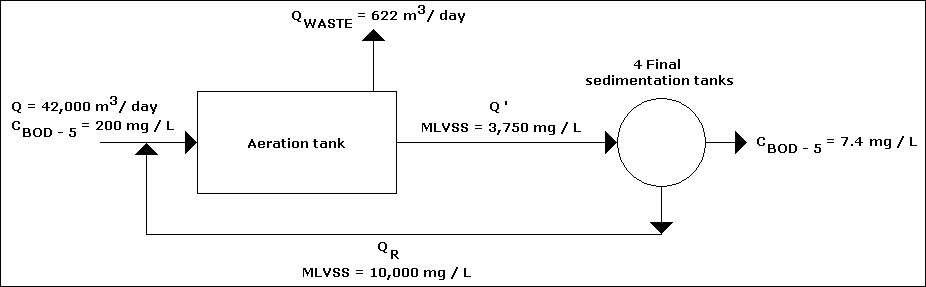

Q - 1 ( a ) : For the activated sludge process shown in figure given below calculate the theoretical oxygen requirement for the aeration tank, and the SOR under field conditions and the volume of air required. Check the

volume of air per Kg BOD 5 removed, per m 3 of wastewater treated and per m 3 of

aeration tank volume ( SOR, standard oxygen requirement ).

Given :

- Minimum D.O. concentration in the aeration tank = 1.5 mg / L

- ALPHA = 0.95

- BETA = 0.90

- Elevation = 500 m

- BOD 5 / BOD L = 0.68

- Aeration tank temperature = 24 OC

- Atmospheric pressure = 102,063 Pa

- Density Hg = 13,600 Kg / m 3

- Density air = 1.201 Kg / m 3

- Diffuser efficiency = 8 %

- Design air = 1.5 ( Theoretical air )

- Y = 0.50

- k D = 0.10 1 / day

- THETA C ( Solids retention time ) = 10 days

- Volume of the aeration tank = 8,649 m 3

- Air contains 23.2 % O 2 by weight

Q - 1 ( b ) : Calculate the design flow to the four secondary clarifiers. Prepare a solids flux curve and hence determine the limiting solids loading rate given the following data.

Determine the area and diameter of the secondary clarifiers, and the overflow rate. Does the clarification meet design criteria ?

Given :

Q - 2 ( a ) : For the rotating biological contactor shown in figure given below shows that :

Q - 2 ( b ) : Assume a single stage R.B.C. is to be constructed to treat a waste water flow of 0.1 MGD with a

strength of 250 mg / l BOD 5 A treatability study has revealed that P = 2,500 mg / ft 2 day and

K S = 100 mg / l. How much surface area will be required if a soluble effluent BOD 5 of 15

mg / l is desired ?

Q - 3 ( a ) :

( i ) Derive an expression to allow calculation of the ratio ( S e / S i ).

S e is the effluent concentration and S i is the influent concentration.

(ii) Size a two stage trickling filter system to treat a waste water flow of 2 MGD with a strength of 400 mg / l

BOD 5. Each filter is to be 8 ft deep and operated at a recirculation ratio of 4 : 1. A 90 % BOD 5 removal is desired. For the most effective design, the volume of the two filters should be approximately the same.

Given :

( C1 - EFFLUENT / C1 - INFLUENT ) = ( 0.0561 ) { ( W 1 ) / [ ( V 1 ) ( F ) ] } 1 / 2 / { 1 + ( 0.0561 ) { ( W 1 ) / [ ( V 1 ) ( F ) ] } 1 / 2 }

Where ;

C1 - INFLUENT : Influent BOD 5 concentration for the first TF ( mg / L )

C1 - EFFLUENT : Effluent BOD 5 concentration for the first TF ( mg / L )

W1 : BOD5 loading for the first TF ( lb / gün )

V1 : Volume of the first TF ( ft 3 )

F : Recycling factor

F = ( 1 + R ) / [ 1 + ( 1 - j ) ( R ) ] 2

Where ;

R : Recycling ratio

j : Factor ( = 0.81 - 0.95 )

( C2 - EFFLUENT / C2 - INFLUENT ) = ( 0.0561 ) { ( W 2 ) / [ ( V 2 ) ( F )

( C1 - EFFLUENT / C1 - INFLUENT ) ] } 1 / 2 / { 1 + ( 0.0561 ) { ( W 2 ) /

[ ( V 2 ) ( F ) ( C1 - EFFLUENT / C1 - INFLUENT ) ] } 1 / 2 }

Where ;

C2 - INFLUENT = C1 - EFFLUENT : Influent BOD 5 concentration for the second TF

( mg / L )

C2 - EFFLUENT = CSTANDARD : Effluent BOD 5 concentration for the second TF ( mg / L )

W2 : BOD5 loading for the second TF ( lb / gün )

V2 : Volume of the second TF ( ft 3 )

Q - 3 ( b ) : Briefly describe the functions of the various physical and chemical operations and processes used for wastewater treatment which are listed below. Indicate whether these operations and processes are used in primary, secondary or tertiary treatment.

Operation / Process...

- Coarse screening.

- Flocculation.

- Sedimentation.

- Chemical precipitation.

Q - 4 ( a ) : Draw a labelled schematic diagram of an aerated grit chamber.

Q - 4 ( b ) : Discuss the operation of this type of grit chamber.

Include the following items in your discussion :

(i) Removal of particles.

(ii) Velocity of roll or agitation.

(iii) Flow pattern of the wastewater in the chamber.

(iv) Grit collection.

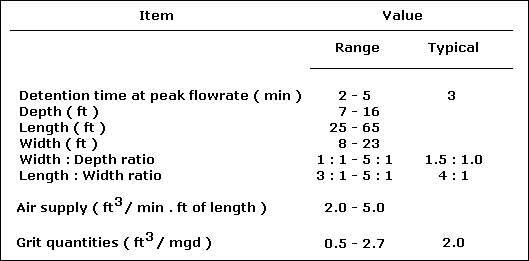

Q - 4 ( c ) : Design an aerated grit chamber for the treatment of municipal wastewater. The average flow rate is

0.6 m 3 / sec. Assume that the peaking factor is 2.5. ( Refer to Table 1 for further data ).

(i) Calculate the peak design flow rate.

(ii) Calculate the grit chamber volume. It will be necessary to drain the chamber for routine maintenance.

(iii) Calculate the dimensions of the grit chamber. Use a width to depth ratio of 1.2 : 1.

(iv) Calculate the air supply requirement.

(v) Estimate the average quantity of grit that must be handled per day.

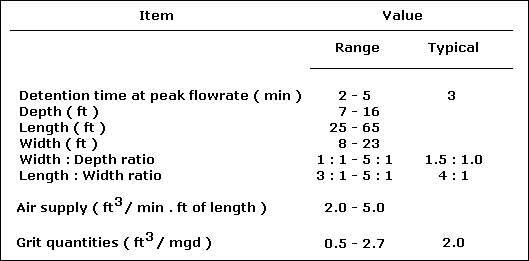

Table 1. Typical Design Information for Aerated Grit Chambers

Q - 5 ( a ) : Why is it necessary to conduct wastewater characterisation studies ?

Q - 5 ( b ) : Discuss the procedures for wastewater sampling under the following headings :

(i) Sampling techniques.

(ii) Sampling locations.

(iii) Sampling intervals.

(iv) Sampling equipment.

(v) Sample preservation.

Q - 6 : You have just been appointed to the position of Environmental Director with Lone Ranger Chemicals, a Multinational Conglomerate. Your new employers have recently been severely punished in a number of countries as a

result of non-compliance with air pollution licences due to gaseous emissions. What advice would you give to your

fellow directors on the options available to the company if it wishes to avoid non-compliance in the future ?