A / O ® Process...

Biological Selector for Activated Sludge Systems...

The A/O® Process improves upon the activated sludge process by using an anaerobic selector to develop a selective

biomass that is naturally reoccurring in nearly all treatment plants. The process enhances phosphorus removal while

reducing sludge-bulking organisms...

Description...

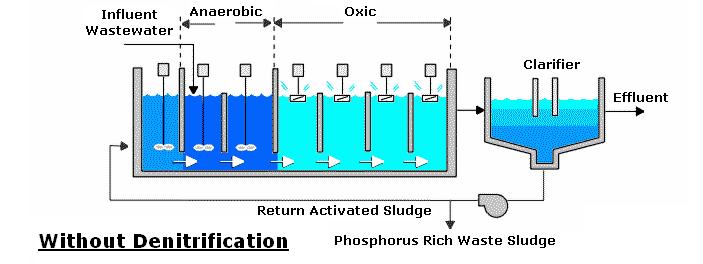

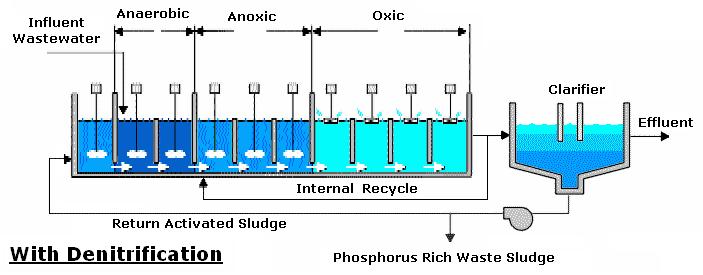

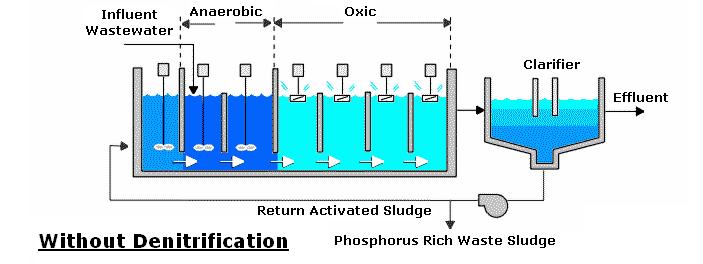

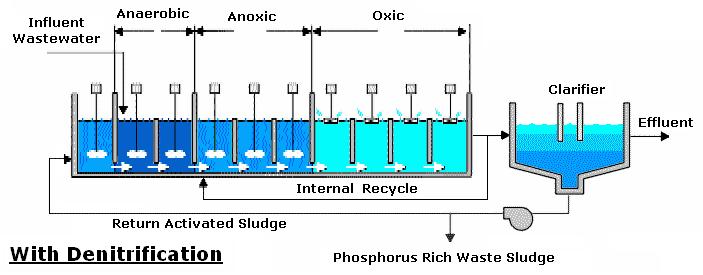

The A/0 process improves upon the activated-sludge process by using an anaerobic selector to develop a biomass. This

biomass first stores BOD anaerobically and then assimilates phosphorus in a subsequent oxic, or aerobic zone. Because

its operation uses anaerobic uptake of BOD, the process particularly resists hydraulic and organic upsets. It also

minimizes the presence of Nocardia and other sludge-bulking organisms commonly found in activated sludge plants. The

A/0 process for secondary treatment has been proven reliable and cost-effective through extensive pilot testing and

actual full-scale plant operation.

Applications...

Secondary or advanced treatment requirements with air- or oxygen-activated sludge.

Process control problems resulting from sludge-bulking or wide swings in organic loading.

Increasing rated design organic load but limited available space to expand.

Discharge permit may require nutrient control in the future.

Features and Benefits...

Non-Bulking Sludge :

Resistant to proliferation of bulking organisms.

Superior Settling Characteristics :

Settles rapidly and compacts well.

Precise process control.

Improved thickening and dewatering properties.

Improved Stability :

Anaerobic selector permits operation over a wide range of hydraulic and organic loading conditions.

Ease of Operation :

Equipment is common to most treatment plants.

Physical layouts and flow schemes are similar to conventional activated- sludge plants.

Reduced Construction Cost :

High-rate design results in less tankage.

Better use of existing facilities.

Air or Oxygen Aeration :

Compatible with either air or pure oxygen aeration systems (e.g., OASES ).

Technical Description...

A basic A/0 system will yield simultaneous biological removal of both BOD and phosphorus. Where only BOD removal is

required, the basic process is optimized to provide significant performance benefits relative to conventional activated-sludge processes. In either case, the same basic configuration and biological processes, shown above, are

utilized. The A/0 process, which uses an anaerobic selector to achieve enhanced performance, is a high-rate variation

of the conventional activated-sludge process. The anaerobic selector is established by mixing and contacting influent BOD-containing wastewater with recycled activated sludge in the absence of supplied oxygen or oxygen-containing gas.

In a subsequent step, the anaerobically formed mixed liquor is aerated in an oxic zone and finally separated in a

secondary clarifier, which functions in the same manner as in conventional activated-sludge processes.

Anaerobic Zone...

Anaerobic zone detention time is set at the minimum necessary to ensure the development and maintenance of the A/0

system biomass, without concern for maximizing phosphorus release. For municipal waste, this is typically between 30

and 60 minutes based on the design-average flow of influent. As the wastewater passes through the anaerobic zone, most

of the influent BOD is absorbed into the biomass. BOD, both sorbed and unsorbed, is then oxidized in the oxic zone.

Oxic Zone...

Various laboratory, pilot-plant, and full-scale studies have shown that an A/0 system will remove BOD when oxic

detention time is less than the minimum time needed to fully oxidize the BOD stored within the A/0 biomass. This

biomass will function acceptably for BOD removal while maintaining a reservoir of stored, unoxidized BOD within the

sludge. This unoxidized BOD is removed from the system through the normal wasting of sludge from the system. Since

oxygen requirements are directly related to the amount of BOD oxidized, operating the A/0 system with- out fully

oxidizing the BOD in the oxic section allows for a net reduction in the amount of oxygen that must be transferred

into the mixed liquor. The net result is a reduction in oxygen or horse- power used for the same amount of BOD removal compared to a conventional activated-sludge system. Oxygen savings of 15 percent or more can be achieved for A/0 systems compared to conventional activated-sludge systems. The detention time of the oxic zone is determined by the rate of biological oxidation of stored BOD, the rate of sorption and oxidation of unstored BOD, the degree of oxidation desired,

and mass transfer characteristics of the aeration equipment.