Friction Losses...

Pipe Fittings...

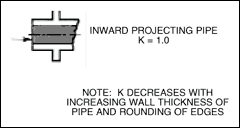

Invariably a system containing piping will have connections which change th size and / or direction of the conduit.

These fittings and friction, called " minor losses ", to the system head. Fitting losses are generally the result of

changes in velocity and / or direction. A decreasing velocity results in more loss in head than an increasing velocity

as the former causes energy - dissipating eddies. Experimental results have indicated that minor losses vary approximately

as the square of the velocity through the fittings.

Valves and Standard Fittings...

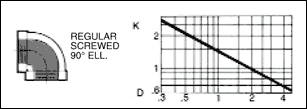

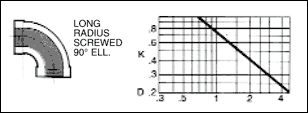

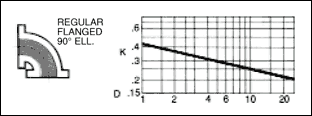

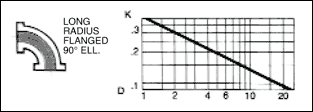

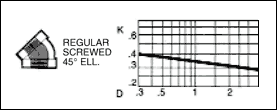

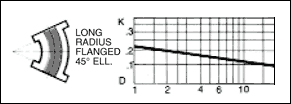

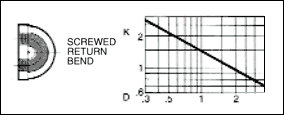

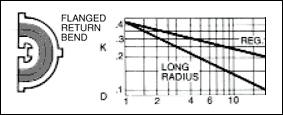

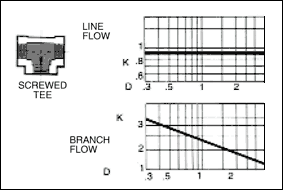

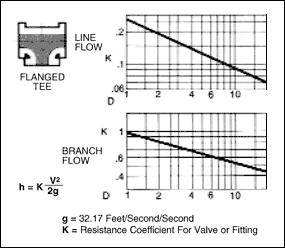

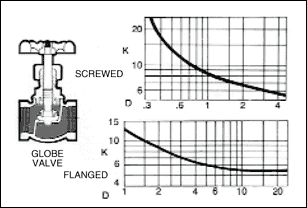

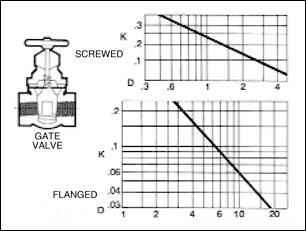

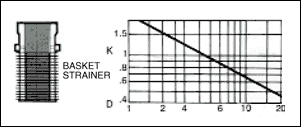

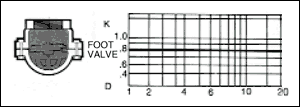

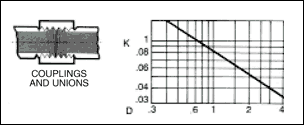

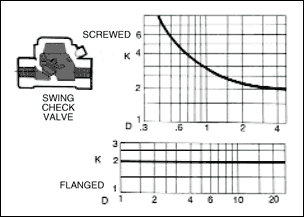

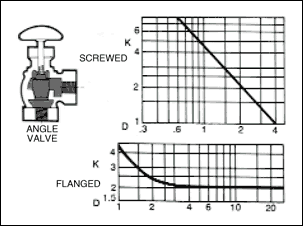

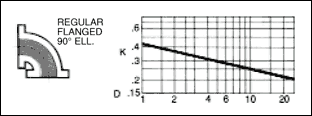

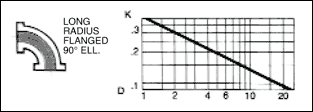

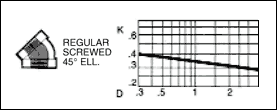

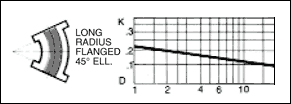

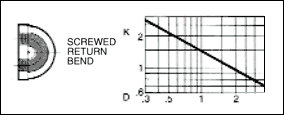

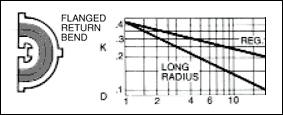

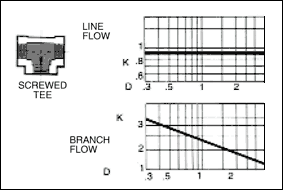

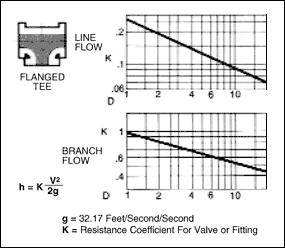

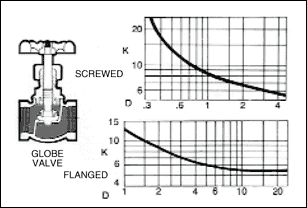

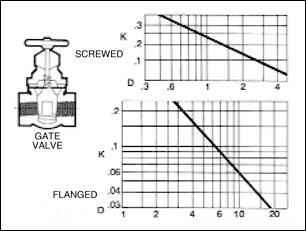

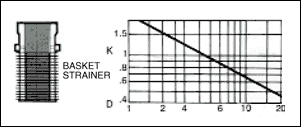

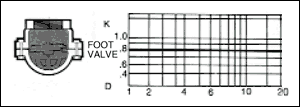

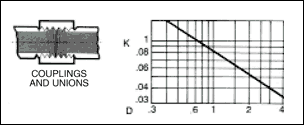

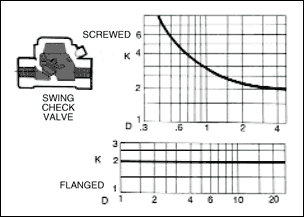

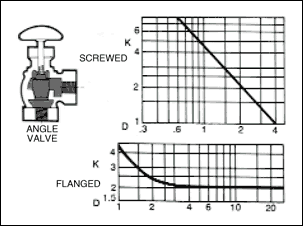

The resistance to flow through valves and fittings may be estimated by any of the following methods. The " Hydraulic

Institute - Pipe Friction Manual ", lists losses through valves and fittings in terms of the average velocity head

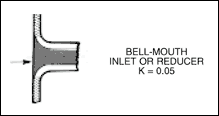

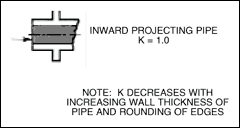

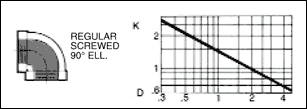

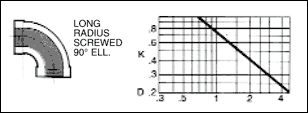

in a pipe of corresponding diameter and a " resistance coefficient " as shown in figures given below.

Source : www.gouldspumps.com

The frictional resistance in feet is found from the equation ;

h= ( K ) ( V 2 / 2 x g )

where ; K : resistance coefficient which depends on design and size of valve or fitting, V : average velocity in pipe of

corresponding diameter ( ft / s ) and g : acceleration of gravity ( = 32.17 ft / s 2 ).

Table given below indicates the wide variation in published values of K.

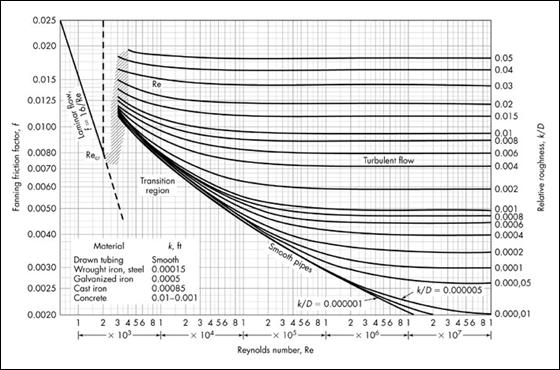

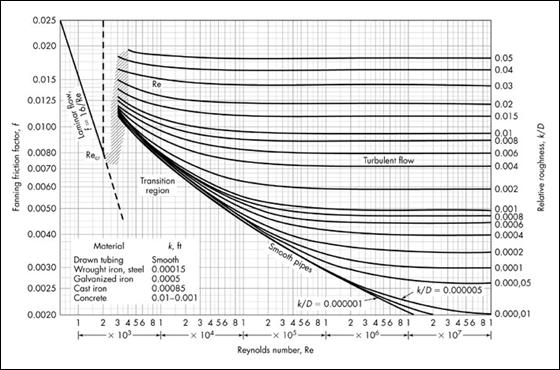

A comparison of the " Darcy - Weisbach " equation and the above equation suggests that K = f ( L / D ) to produce the same

head loss in a straight pipe as in the valve or fitting. The ratio ( L / D ) or " equivalent length in pipe diameters "

of straight pipe may then be used as another method to estimate valve and fitting losses. Tests have shown that while

K decreases with size of different lines of valves and fittings, ( L / D ) is almost constant. In the zone of complete

turbulence, as shown in figure below, K for a given size and ( L / D ) for all sizes of valves and fittings are constant.

In the transition zone K increases as does the friction factor f with decreasing.

" Reynolds " number Re while L / D remains approximately constant. Table given below lists suggested values of L / D for

various valves and fittings.

Multiplying L / D by the inside diameter of pipe corresponding to the schdule number shown in table given below gives the

equivalent length of straight pipe.

When using the equivalent length method, the friction head loss is determined by employing the " Darcy - Weisbach "

equation. This method therefore takes into consideration the viscosity of the liquid, which in turn determines the

" Reynolds " number and the friction factor.

The loss of head through valves, particularly control valves, is sometimes expressed in terms of the " flow coefficient,

C V ". The flow in gpm at 60 O F to produce a pressure drop of 1 lb / in 2 is defined

as the flow coefficient for a particular valve opening. Values of C V may be obtained from various

manufacturers for their different lines of valves. The pressure loss for liquids with viscosity close to water at

60 O F may be found for different flows from ;

lb / in 2 = sp gr at 60 O F ( gpm / C V ) 2

The following examples illustrate the use of the " resistance coefficient, K " and the " equivalent length in pipe

diameters, L / D " methods for estimating losses in valves and fittings.

Example - 1...

A pumping system consists of 20 ft of 2 - in suction pipe and 300 ft of 1 1/2 - in discharge pipe, both " Schedule "

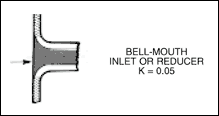

40 new steel. Also included are a bellmouth inlet, a 90 O LR suction elbow, a suction - gate valve, a

discharged - gate valve and a swing - check valve. The valves and fittings are screw - connected and the same size

as the connecting pipe. Determine the pipe, valve, and fitting losses when pumping 60 gpm of 60 O F oil

having a sp gr of 0.855. Use the resistance coefficient method.

Solution...

- Suction pipe :

* ID = 2.067 in

* EPSILON / D = 0.00087

* NU = 0.0009 ft 2 / s

* V = ( 60 / 2.067 2 ) ( 0.408 ) = 5.73 ft / s

* ( V ) ( D" ) = ( 5.73 ) ( 2.067 ) = 11.8 ft / sec . in

* Re = 1 x 10 4

* f = 0.032

h FS = ( 0.032 ) [ ( 20 ) ( 12 ) / ( 2.067 ) ] [ ( 5.73 2 ) / ( 2 ) ( 32.17 ) ] = 1.9 ft

- Discharge pipe :

* ID = 1.610 in

* EPSILON / D = 0.0011

* NU = 0.00009 ft 2 / s

* V = ( 60 / 1.610 2 ) ( 0.408 ) = 9.44 ft / s

* ( V ) ( D" ) = ( 9.44 ) ( 1.610 ) = 15.2 ft / sec . in

* Re = 1.5 x 10 4

* f = 0.030

h FD = ( 0.030 ) [ ( 300 ) ( 12 ) / ( 1.610 ) ] [ ( 9.44 2 ) / ( 2 ) ( 32.17 ) ] = 92.9 ft

- Valve and fitting losses :

* 2 - in bellmouth, K = 0.05

h F - 1 = ( 0.05 ) [ ( 5.73 2 ) / ( 2 ) ( 32.17 ) ] = 0.026 ft

* 2 - in LR, 90 O elbow, K = 0.4 +- 25 %

h F - 2 = ( 0.4 ) [ ( 5.73 2 ) / ( 2 ) ( 32.17 ) ] = 0.202 +- 0.051 ft

* 2 - in gate valve, K = 0.16 +- 25 %

h F - 3 = ( 0.16 ) [ ( 5.73 2 ) / ( 2 ) ( 32.17 ) ] = 0.082 +- 0.021 ft

* 1 1/2 - in gate valve, K = 0.19 +- 25 %

h F - 4 = ( 0.19 ) [ ( 9.44 2 ) / ( 2 ) ( 32.17 ) ] = 0.263 +- 0.066 ft

* 1 1/2 - in swing - check valve, K = 2.4 +- 30 %

h F - 5 = ( 2.4 ) [ ( 9.44 2 ) / ( 2 ) ( 32.17 ) ] = 3.32 +- 1.0 ft

- Total pipe, valve and fitting losses :

TOTAL h F = 1.9 + 92.9 + 0.026 + 0.202 + 0.082 + 0.263 + 3.32 = 98.69 ft

TOTAL variation = +- ( 0.202 + 0.021 + 0.066 + 1.0 ) = +- 1.29 ft

Example - 2...

Determine the value and fittings losses in examle given above by the equivalent length pipe diameters method and compare

results.

Solution...

* 2 - in bellmouth, h F - 1 = 0.026 ft

* 2 - in LR, 90 O elbow, L / D = 20

L 2 = ( 20 ) ( 2.067 / 12 ) = 3.44 ft

* 2 - in gate valve, L / D = 13

L 3 = ( 13 ) ( 2.067 / 12 ) = 2.24 ft

* 1 1/2 - in gate valve, L / D = 13

L 4 = ( 13 ) ( 1.610 / 12 ) = 1.74 ft

* 1 1/2 swing - check valve, L / D = 135

L 5 = ( 135 ) ( 1.610 / 12 ) = 18.1 ft

Using f from example given above, total valve and fitting losses are ;

Total valve and fitting losses from example given above ;

TOTAL h F = ( 0.026 + 0.202 + 0.082 + 0.263 + 3.32 ) +- 1.29 = 3.89 +- 1.29 ft

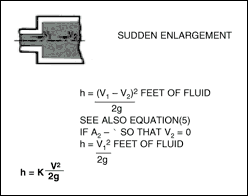

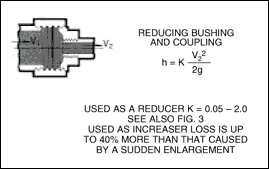

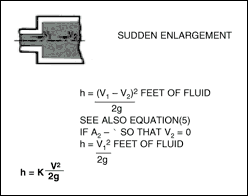

Increasers :

The loss of head for a sudden increase in diameter with velocity changing from V 1 to V 2 in the

direction of the flow can be calculated analytically. Computed results have been confirmed experimentally to be true to

within +- 3 percent. The head loss is expressed as shown below with K computed to be equal to unity ;

The value of K is also approximately equal to unity if a pipe discharges into a relatively large reservoir. This indicates

that all the kinetic energy V 1 2 / 2g is lost, and V 2 equals zero. The loss of head

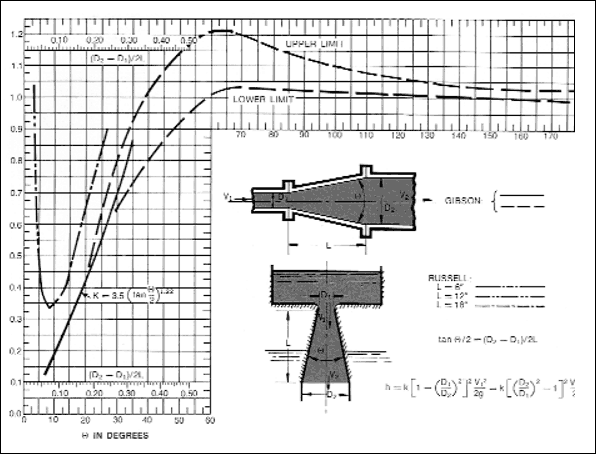

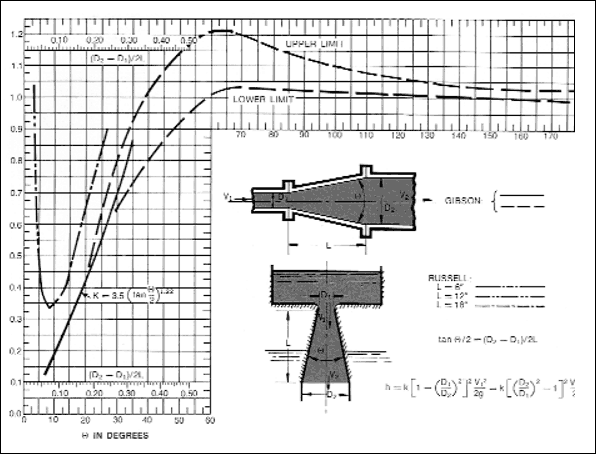

for a gradual increase in diameter through a diffuser can be found from figure given below.

The diffuser converts some of the kinetic energy into pressure. Values for the coefficient used with the above equations

for calculating head loss are shown in the figure. The optimum total angle appears to be 7.5 O . Angles

greater than this result in shorter diffusers and less friction, but separation and turbulence occur. For angles greater

than 50 O it is preferable to use a sudden enlargement.

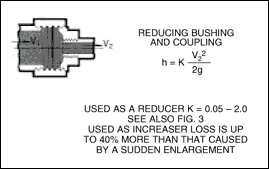

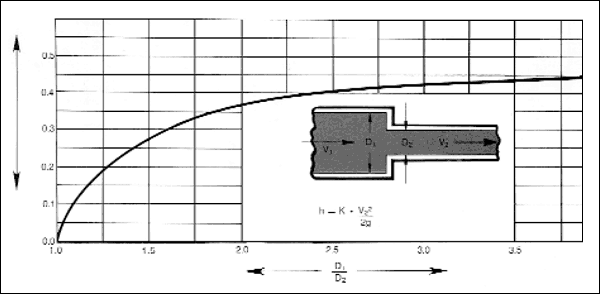

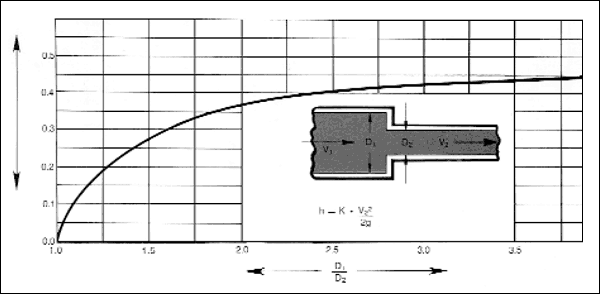

Reducers :

Figure shown below gives values of the resistance coefficient to be used for sudden reducers.

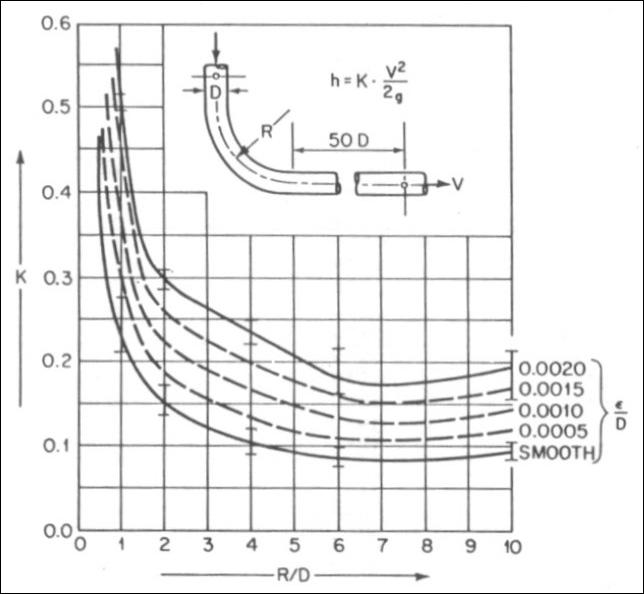

Bends :

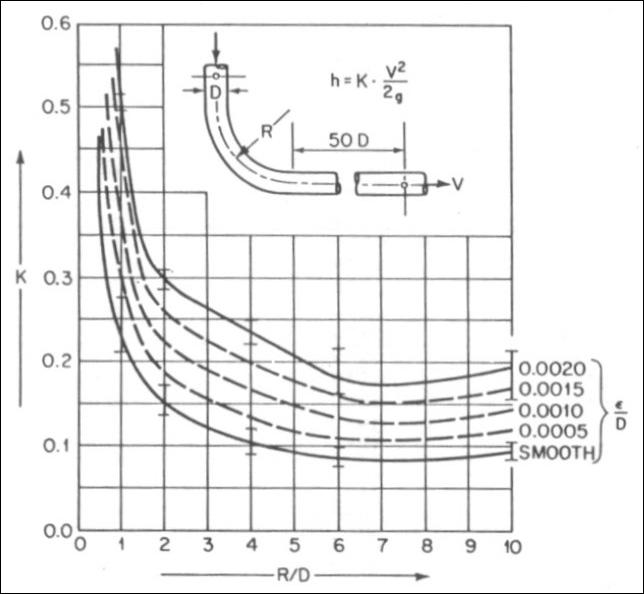

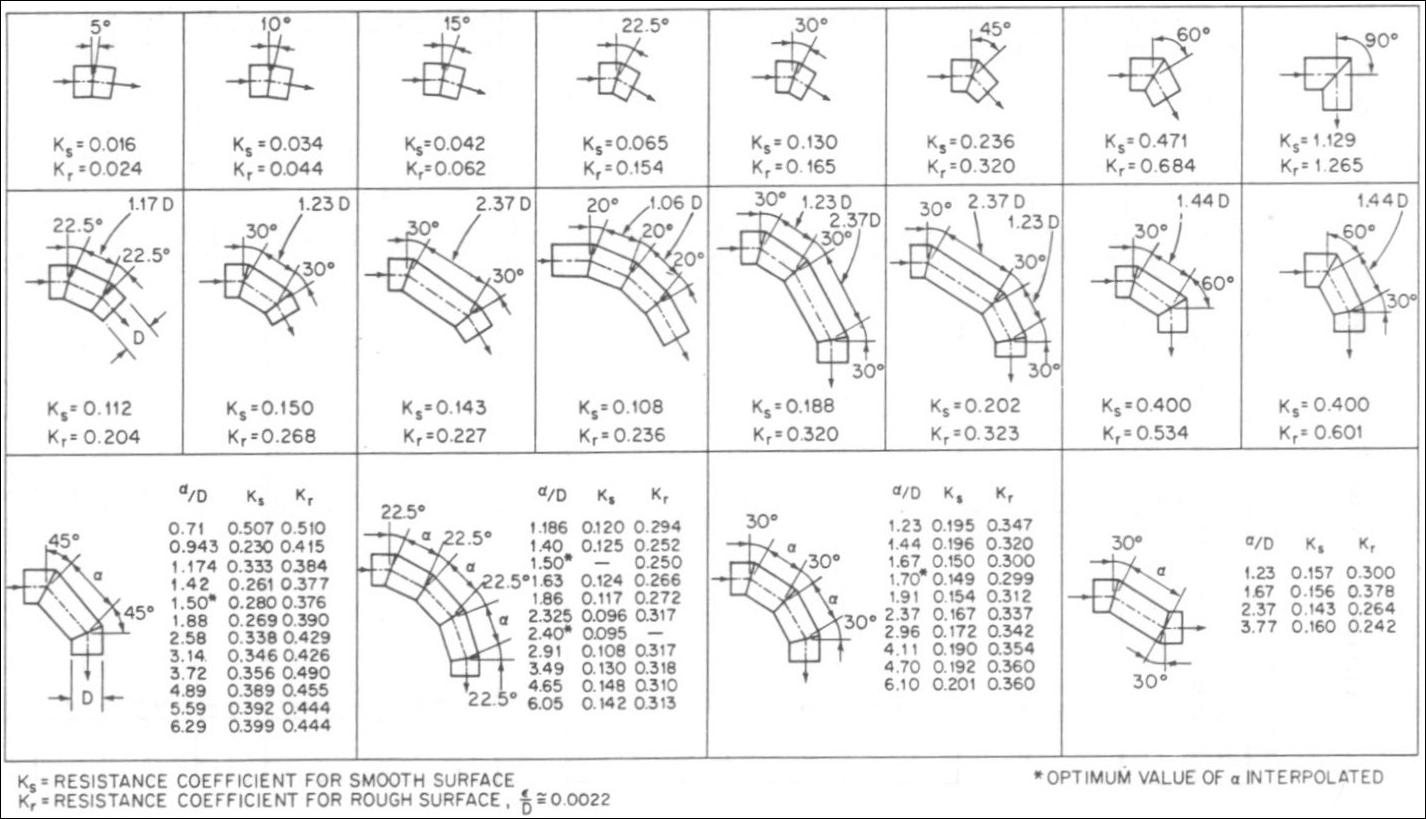

Figure given below may be used to determine the resistance coefficient for 90 O pipe bends of uniform

diameter.

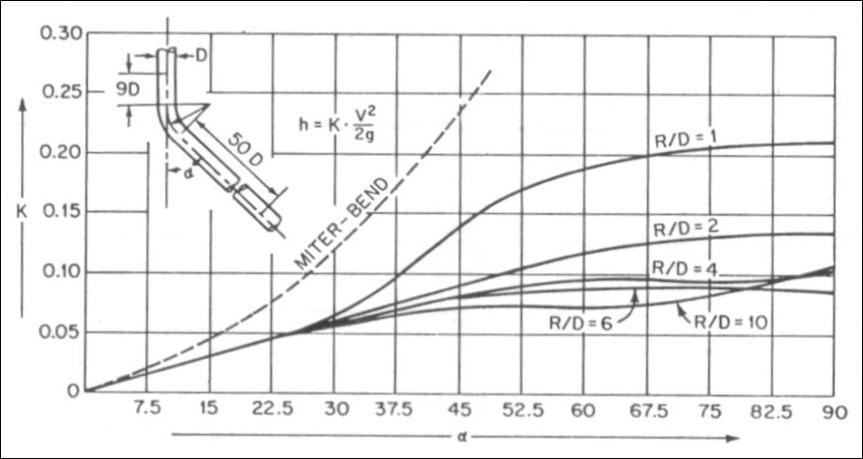

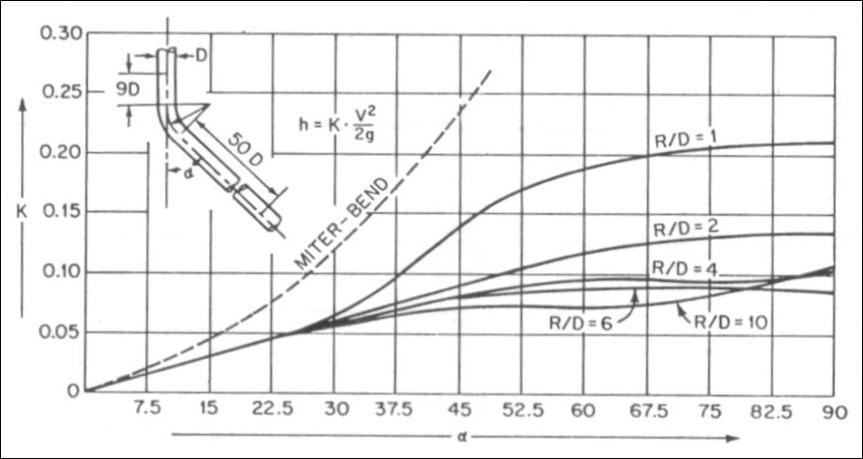

Figure shown below gives resistance coefficients for less than 90 O pipe bends and can be used for surfaces

having moderate roughness such as clean steel and cast iron.

These two figures are not recommended for elbows with R / D below 1.

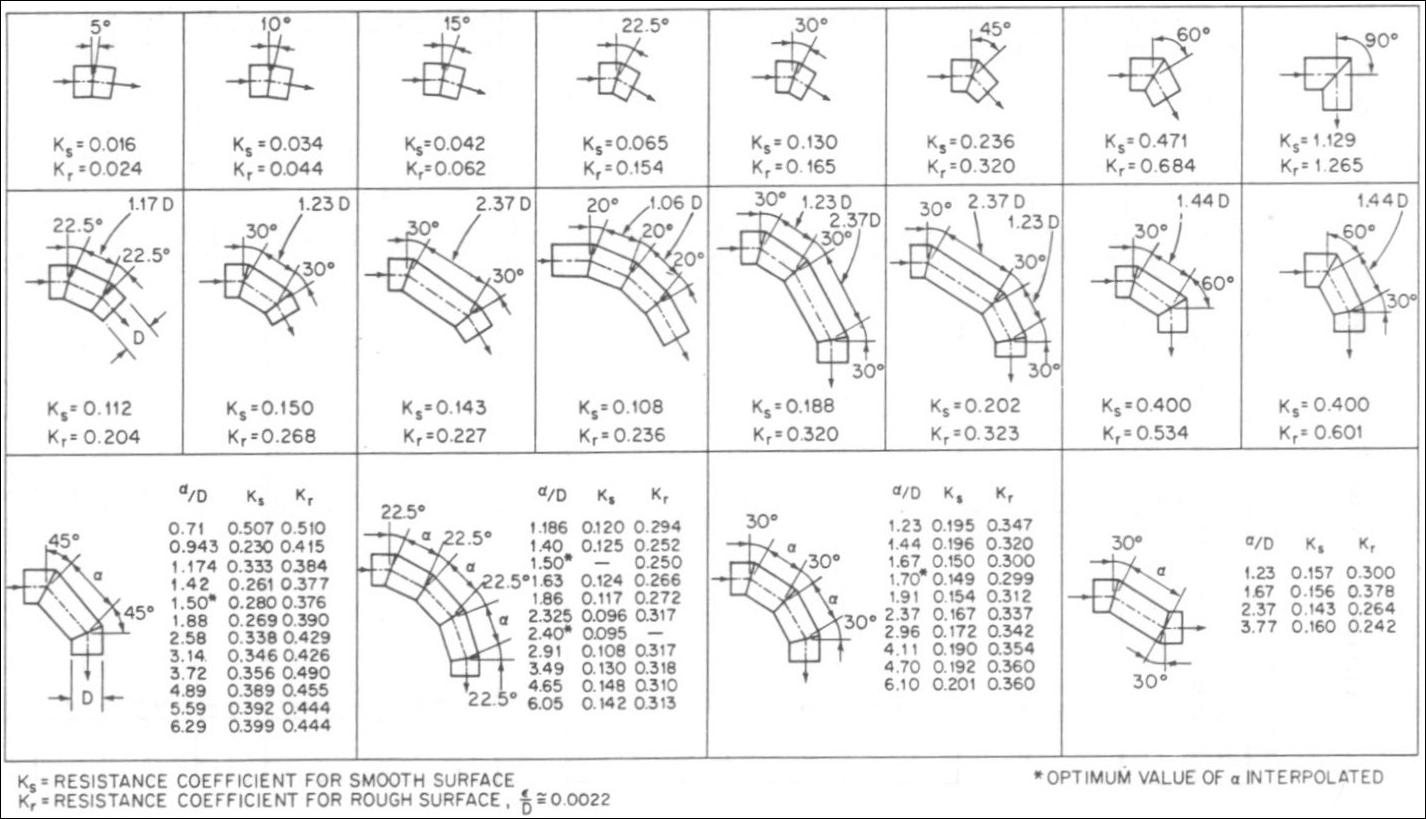

Table shown below gives values of resistance coefficients for miter bends.

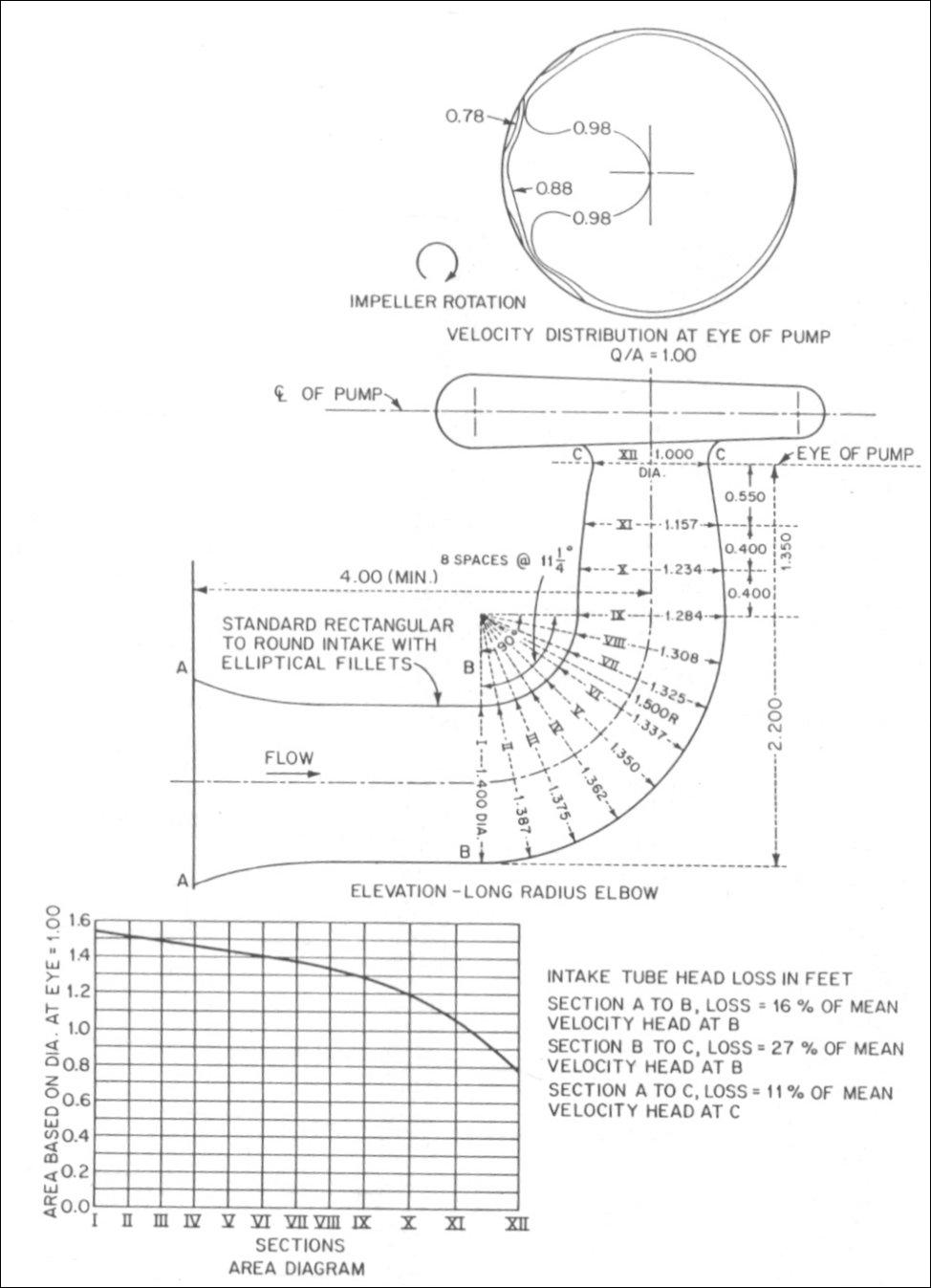

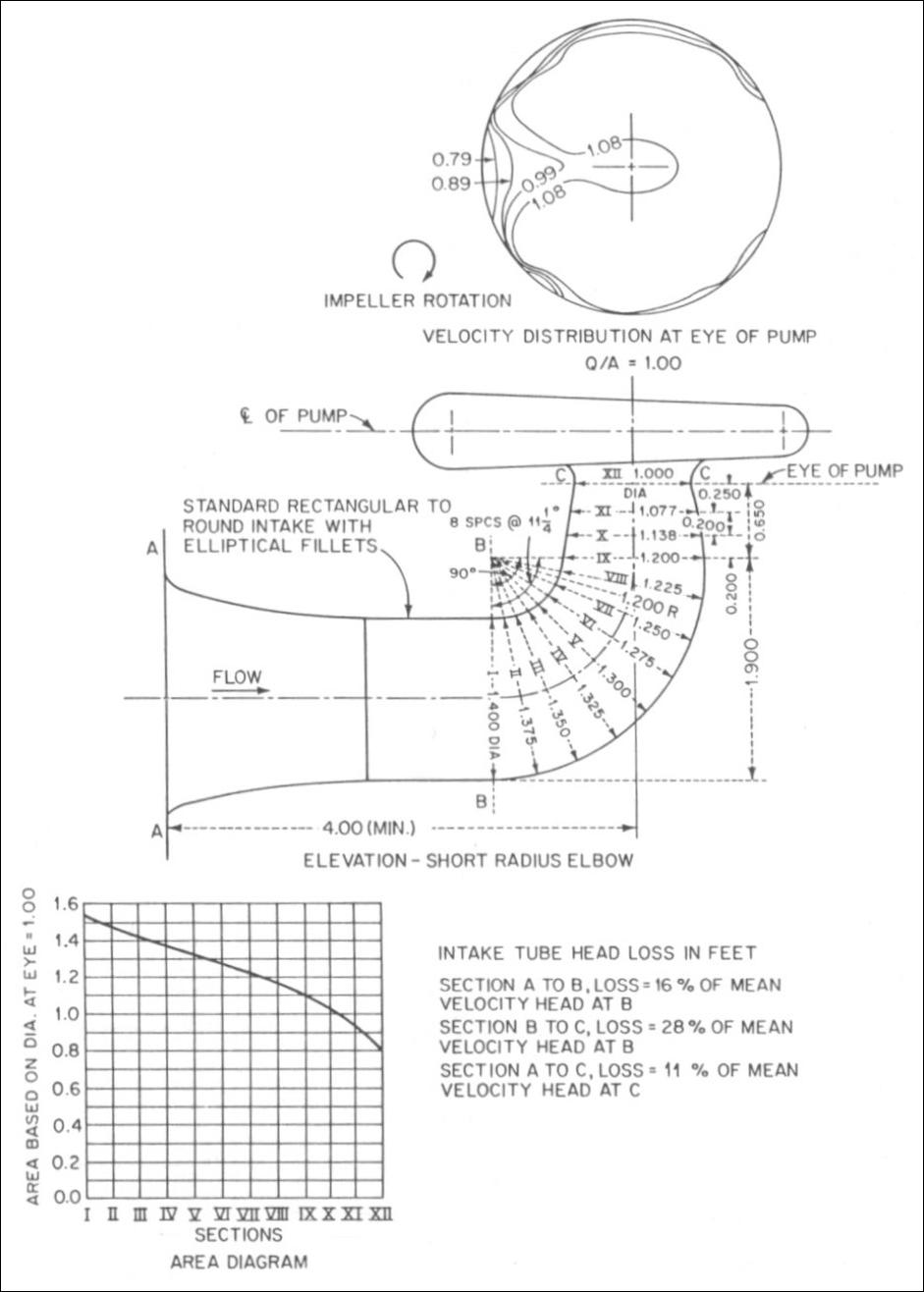

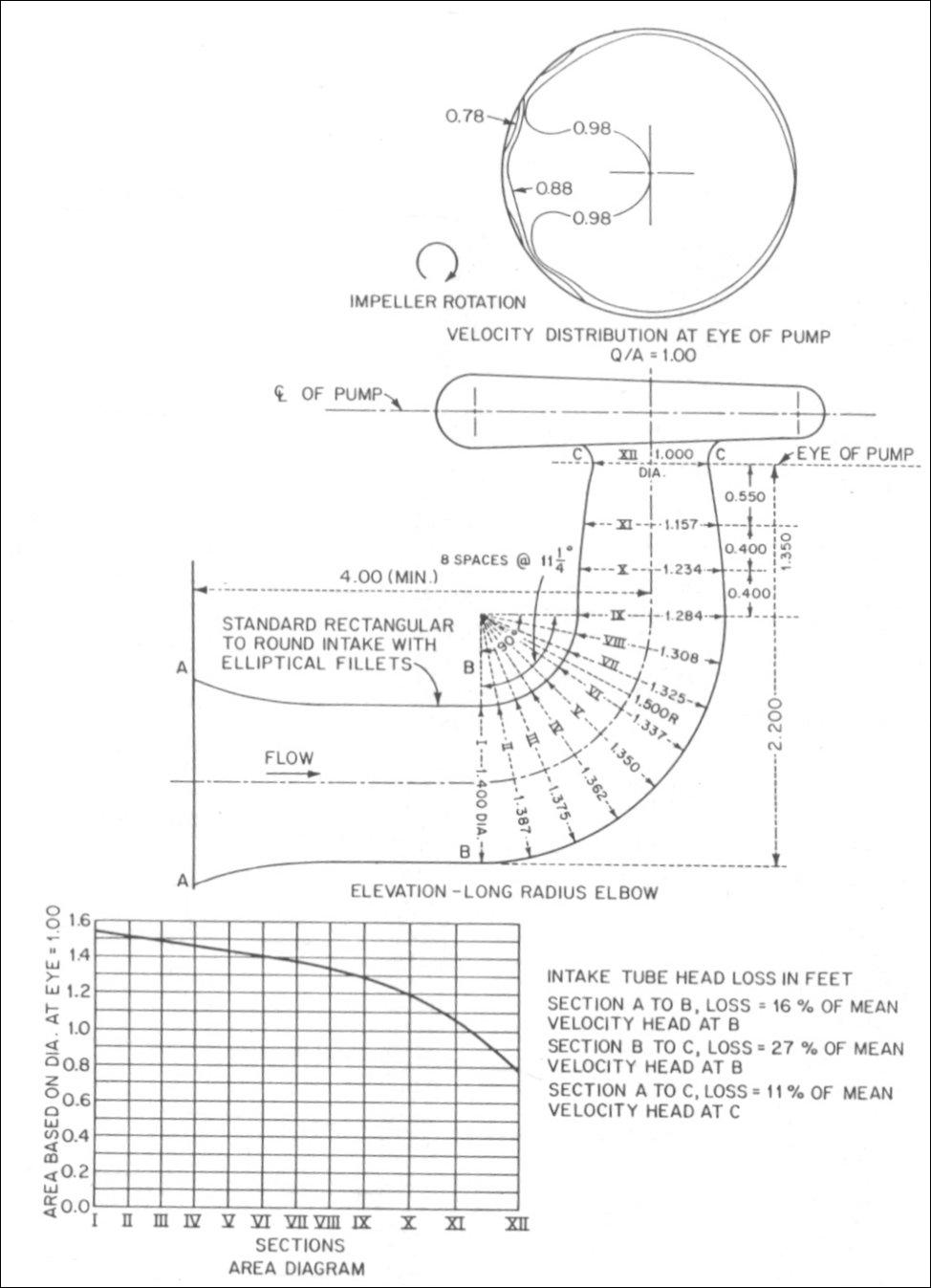

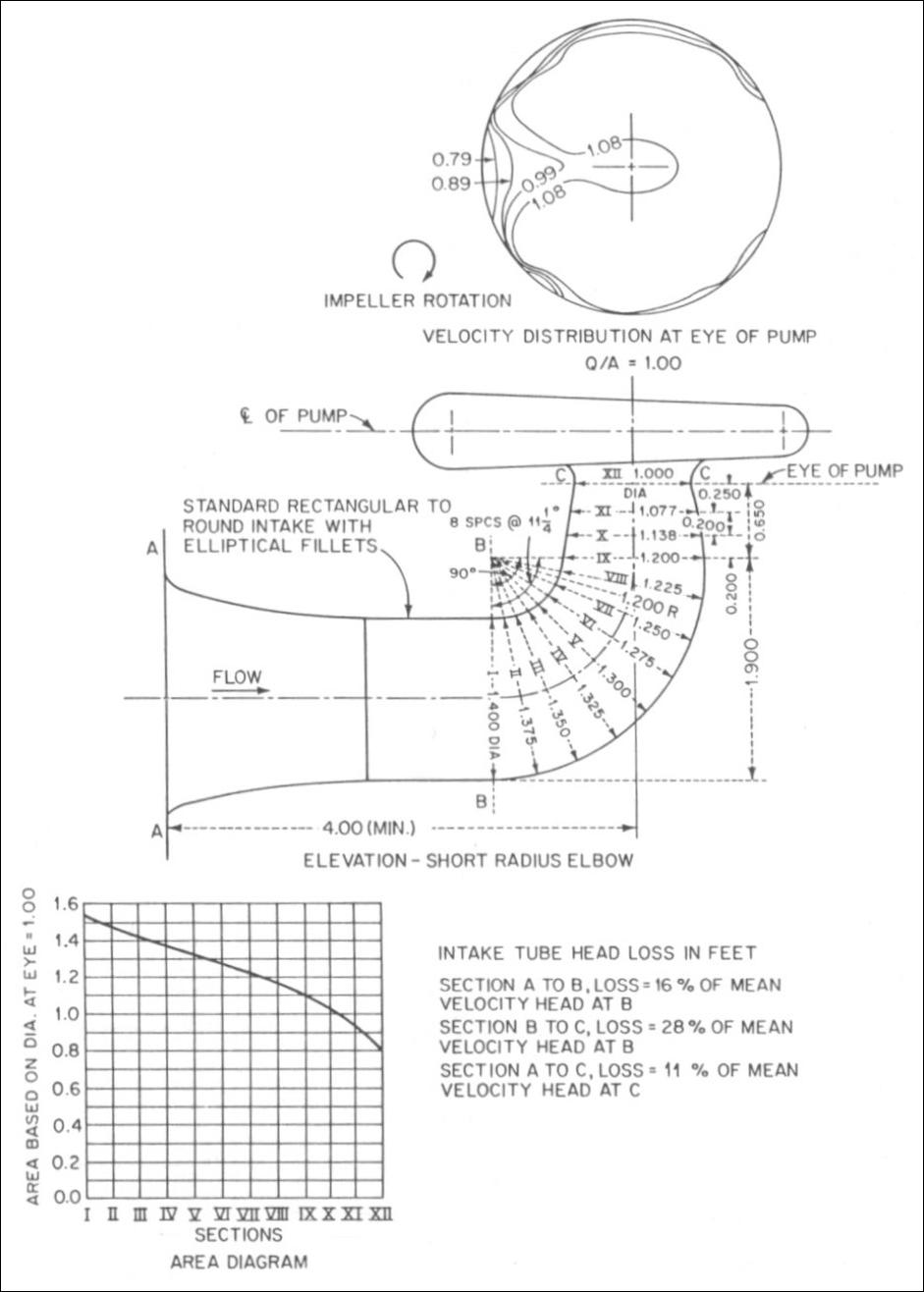

Pump Suction Elbows :

Figures given below illustrate two typical rectangular to round reducing suction elbows. Elbows of this configuration

are sometimes used under dry pit vertical volute pumps. These elbows are formed in concrete and are designed to require

a minimum height, thus permitting a higher pump setting with reduced excavation. Figure (first) shows a long - radius

elbow and figure (second) shows a short - radius elbow. The resulting velocity distribution into the impeller eye and the

loss of head are shown for these selected two designs.

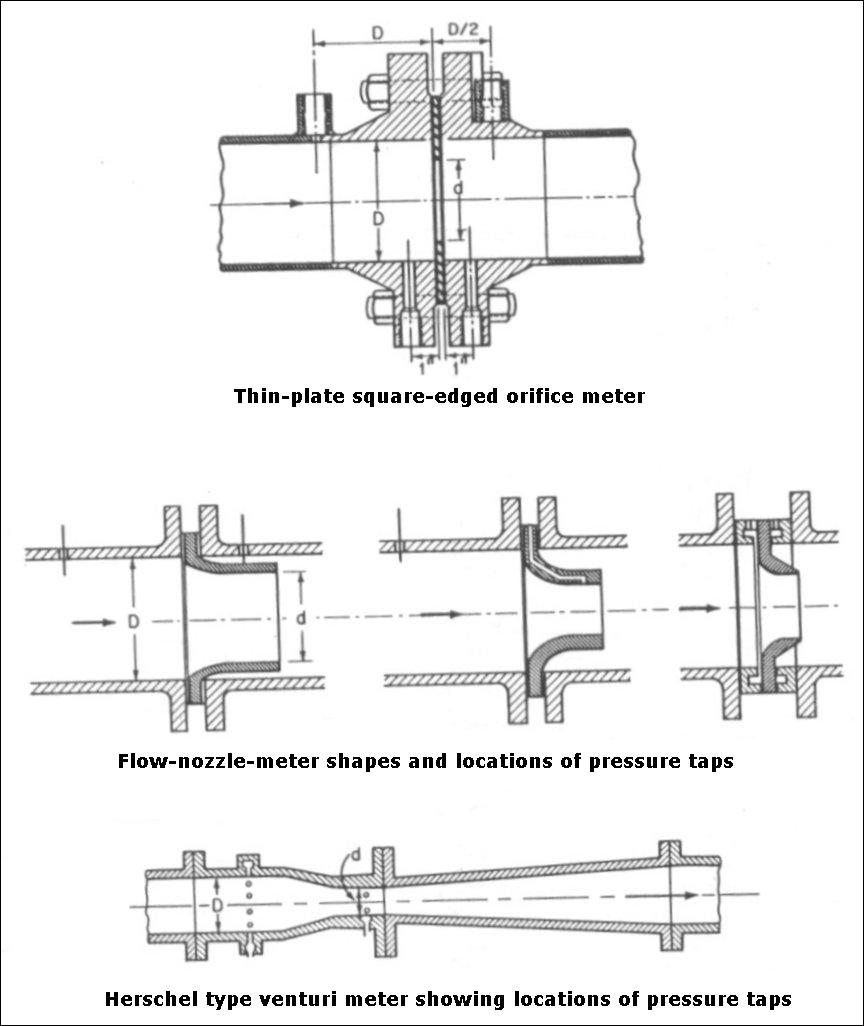

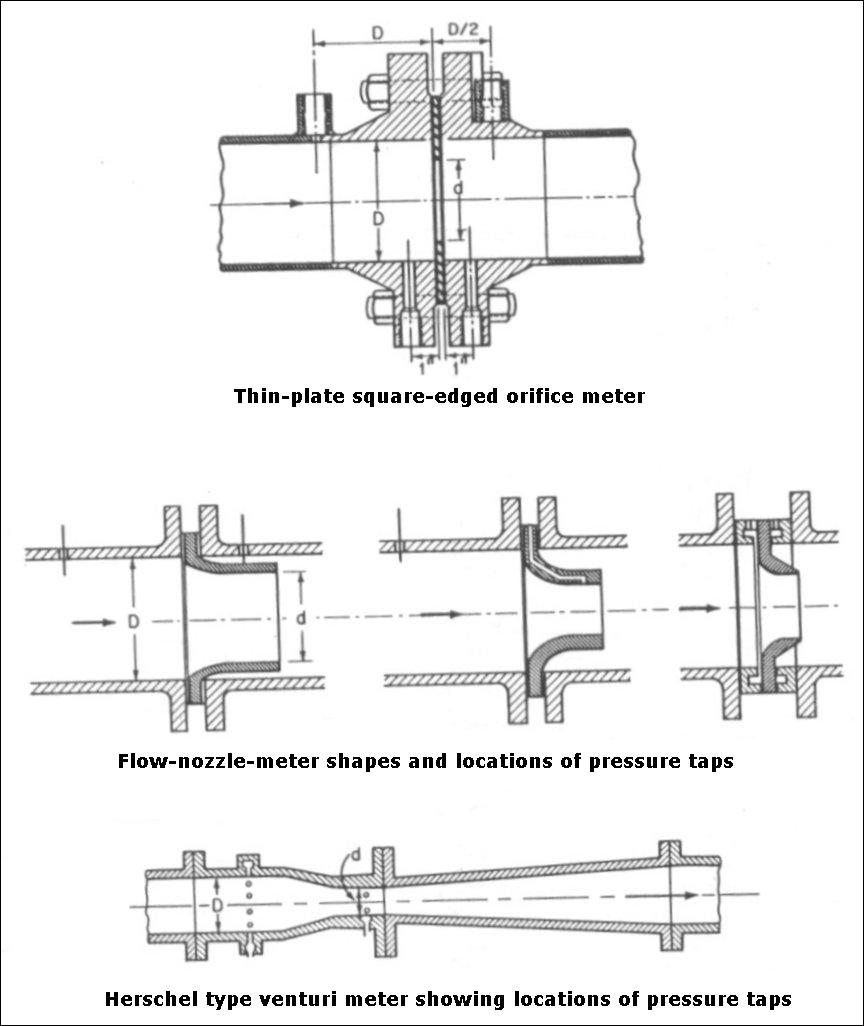

Meters :

Orifices, nozzles, and venturi meters are used to measure rate of flow. These metering devices, however, introduce

additional loss of head into the pumping system. Each of these meters is designed to create a pressure differential through

the primary element. The magnitude of the pressure differential depends on the velocity and the density of the liquid

and the design of the element. The primary element restricts the area of flow, increases the velocity, and decreases the

pressure. An expanding section following the primary element provides pressure head recovery and determines the meter

efficiency. The pressure differential between inlet and throat taps measures rate of flow ; the pressure differential

between inlet and outlet taps measures the meter head loss (an outlet tap is not usually provided). The meters offering

the least resistance to flow are in the following decreasing order ; venturi, nozzle, and orifice. Figures given below

illustrate these different meter designs.

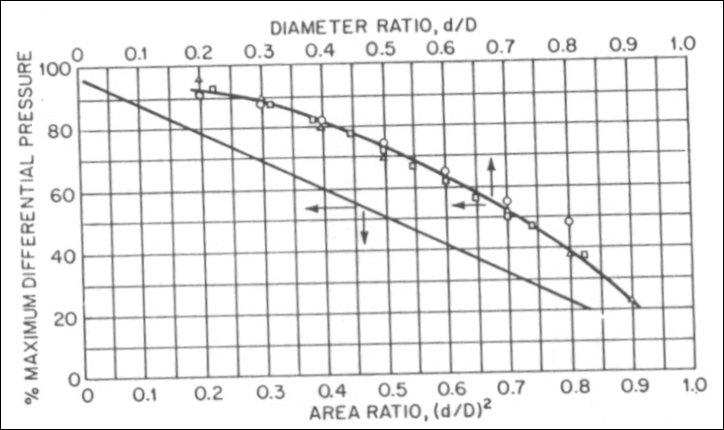

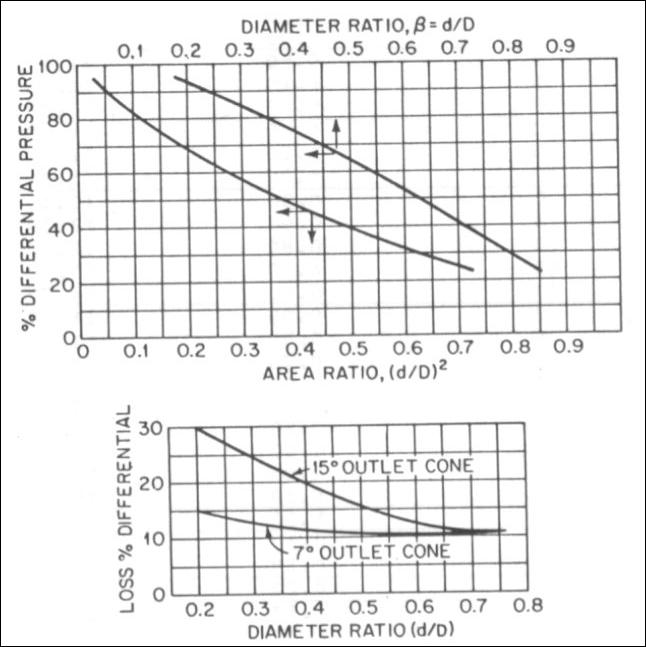

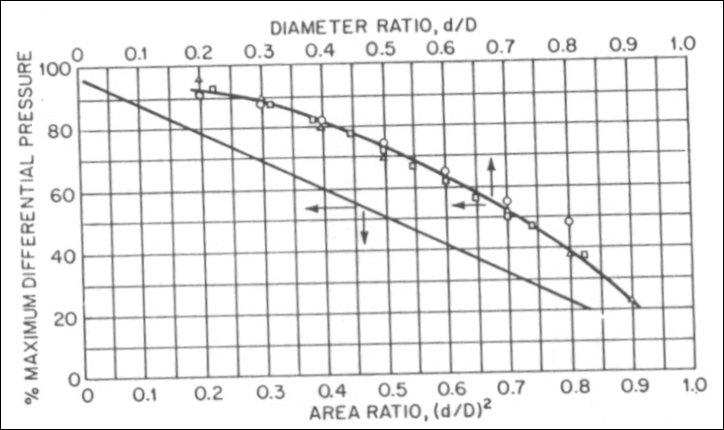

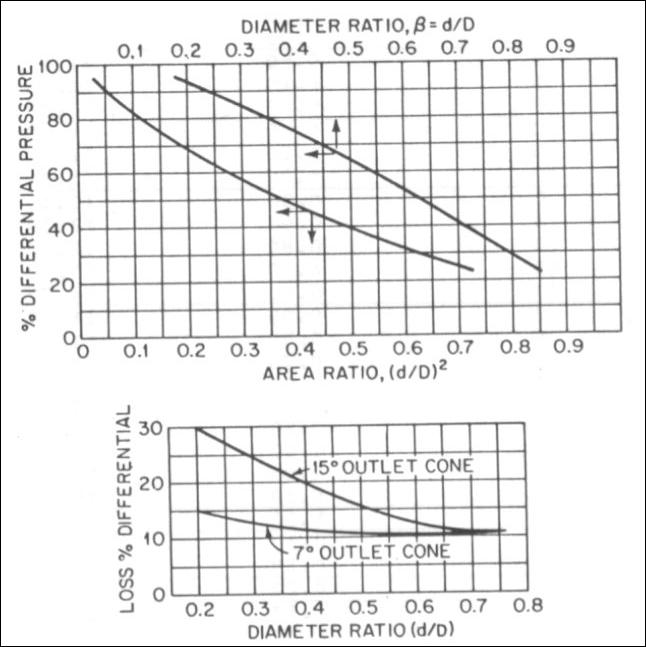

When meters are designed and pressure taps are located as recommended, figures given below may be used to estimate the

overall pressure loss. The loss of pressure is expressed as a percentage of the differential pressure measured at the

appropriate taps and values are given for various size meters.