| Parameter | Concentration ( mg / L ) |

| Total solids | 680 - 1,000 |

| Volatile solids | 380 - 500 |

| Suspended solids (TSS) | 200 - 290 |

| Volatile suspended solids (VSS) | 150 - 240 |

| BOD5 | 200 - 290 |

| Chemical oxygen demand (COD) | 680 - 730 |

| Total nitrogen | 35 - 100 |

| Ammonia (NH3 - N) | 6 - 18 |

| Nitrites and nitrates (NO2 and NO3) | < 1 |

| Total phosphorus | 18 - 29 |

| Phosphate | 6 - 24 |

| Total coliform | 1010 - 1012 |

| Fecal coliform | 108 - 1010 |

| Parameter | 7 sites | 10 tanks | 19 sites | 4 sites | 1 tank |

| BOD5 | |||||

| Mean (mg / L) | 138 | 138 | 140 | 240 | 120 |

| No of samples | 150 | 44 | 51 | 21 | 50 |

| COD | |||||

| Mean (mg / L) | 327 | - | - | - | 200 |

| No of samples | 152 | - | - | - | 50 |

| Suspended solids | |||||

| Mean (mg / L) | 49 | 155 | 101 | 95 | 39 |

| No of samples | 148 | 55 | 51 | 18 | 47 |

| Total nitrogen | |||||

| Mean (mg / L) | 45 | - | 36 | - | - |

| No of samples | 99 | - | 51 | - | - |

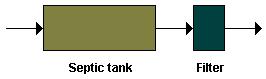

| Capital : Tank (1,000 gallons) installed | $ 2,000 |

| O & M : Pumped once every 3-1/2 yrs. | $ 4.17 / month |

| 20 - year NPW (not including design / permitting costs) | $ 2,498.54 |

| Parameter | Average concentration range (mg / L) |

| BOD5 | 3 - 30 |

| TSS | 10 - 40 |

| NH3 | 70 % - 98 % nitrification |

| Fecal coliform | 2 to 3 log reduction |

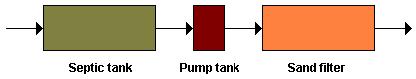

| Estimated initial intermittent sand filter unit costs, installed, and including septic tank for pretreatment, pump, pump tank, control and alarm | $6,500 |

| Equipment (pump) repair / replacement costs, estimated at $ 60 / year) | $5/month |

| O & M (assumes buried intermittent sand filter), with a maintenance contract of $ 240 / year (est. two 180-day filter runs, with system checks and maintenance twice annually) 8 hrs. @ $ 15 / h * 2.0, including taxes, overhead, profit, and including pump / controls servicing | $20/month |

| Septage and sludge pumping once every 2 to 5 years | $4.17/month |

| Energy costs (using 0.051 Kwh / day energy use) | $0.124/month |

| 20 - year NPW (not including design & permitting costs) | $10,002.22 |

| Parameter | Average concentration range ( mg / L ) |

| BOD5 | 5 - 10 |

| TSS | 5 - 10 |

| NH3 | 70 % - 98 % nitrification |

| Fecal coliform | 2 to 3 log reduction |

| Total nitrogen | 30 % - 80 % removal |

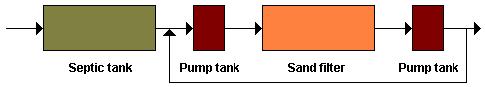

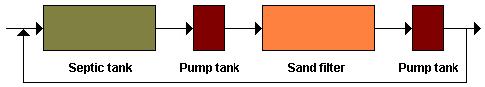

| Estimated initial intermittent sand filter unit costs, installed, and including septic tank for pretreatment, pump, pump tank, control and alarm, and valves | $7,000 |

| Equipment (pump) repair / replacement costs, estimated at $ 60 / year) | $5/month |

| O & M (does not include periodic sand removal / replacement and disposal if / as needed), with a maintenance contract of $ 240 / year (est. two 180 - day filter runs with system checks and maintenance performed twice annually) 8 hrs. @ $15/hour * 2.0, including taxes, overhead, profit, and including pump / controls servicing | $20/month |

| Septage and sludge pumping once every 2 to 5 years | $4.17/month |

| Energy costs (using 0.051 Kwh / day energy use) | $0.124/month |

| 20 - year NPW (not including design & permitting costs) | $10,502.22 |